November 2023

Redefining Large scale production: OTC's Cube 04 Project!

Mönchengladbach 01.11.2023 - Redefining Large scale production: OTC's Cube 04 Project!

Two months ago, OTC DAIHEN EUROPE GmbH successfully completed an exciting Cube 04 project in collaboration with one of our esteemed customers from the automotive supply industry. By transitioning to the OTC SynchroFeed process, we replaced the previous TIG welding process, which enhanced the workflow and met the final customer's requirements. Additionally, the SynchroFeed method, like TIG welding, offers the advantage of low-spatter welding, aligning with the stringent demands of the automotive industry and minimizing the need for post-processing.

The Customer's Vision is Our Challenge

When our automotive customer approached us, their vision was clear: they needed a production system seamlessly integrated into their processes, minimizing downtime and ensuring internal mobility. They required a solution that was quick, reliable, and adaptable to their specific requirements. The OTC SynchroFeed technology in the Cube doubled production output, ensuring the required production quantity.

The SynchroFeed-process, with precise wire feed synchronization, enables high weld deposition with minimal heat input, minimizing material deformations. This technology ensures a uniform and predictable weld penetration that perfectly adapts to welding speed, ensuring a reliable connection between the base material and the weld seam without porosity. The use of SynchroFeed in large scale production thus enables faster, more precise, and cost-effective welding.

The OTC Cube - Redefining Possibilities

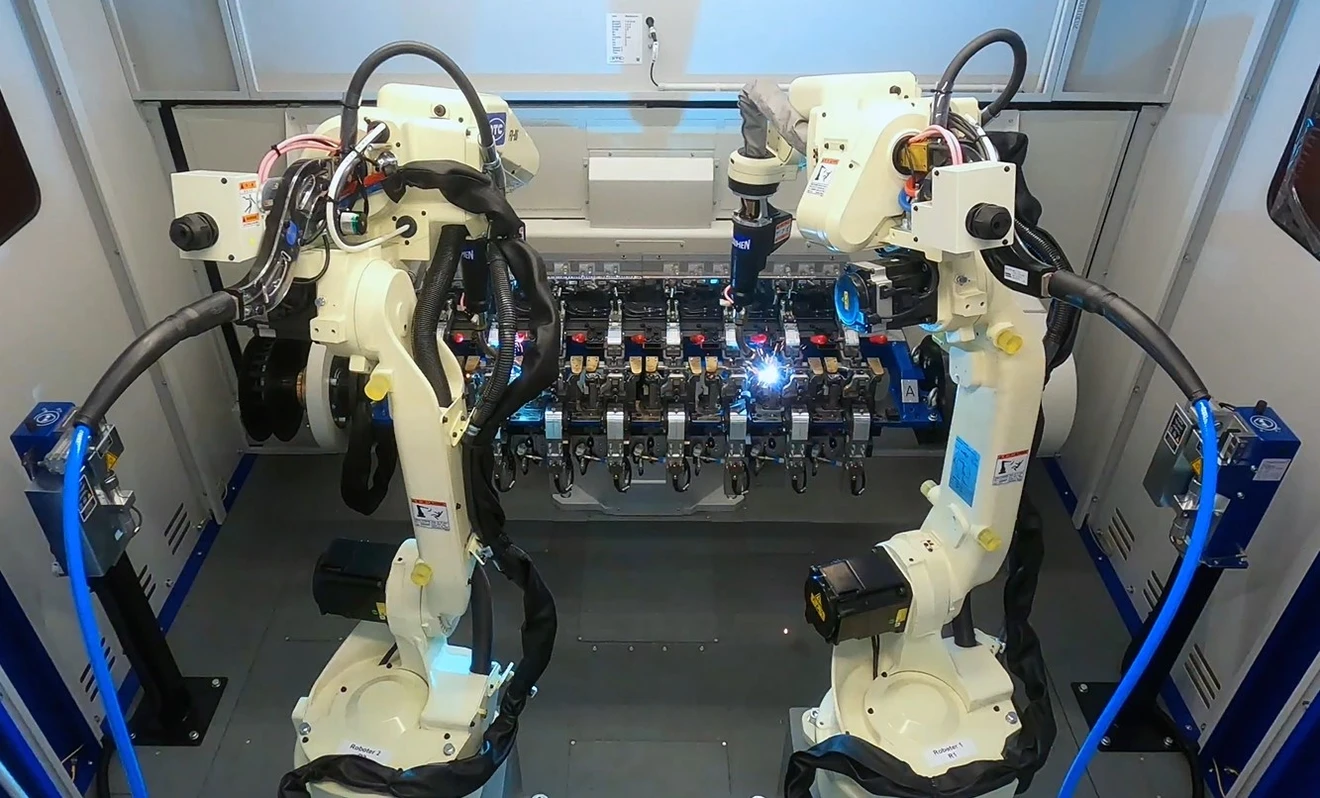

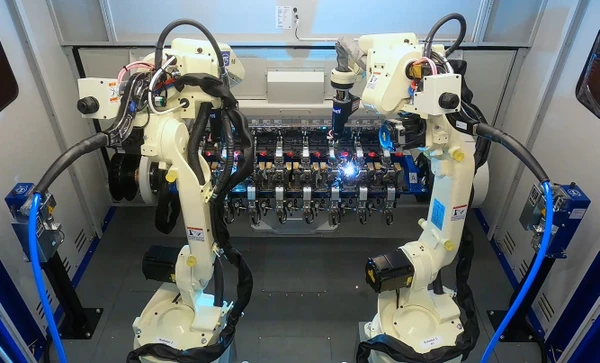

With the OTC Cube 04 (Twin), we had the perfect solution and could deliver an adaptable and error-minimizing welding system. It's a multitasking robot system with two FD19-B6 robots. Additionally, the horizontal positioner HP-1500 enhances precision and efficiency. The process-stable operation and reproducible component placement ensure that each component is automatically checked before the welding process, ensuring correct positioning and clamping in the fixture. To ensure quality requirements, traceability, and continuous quality assurance, the process is supported by OTC- AM-Software.

With the OTC Cube, customers have the option to choose between optional V8 and B6 robots. The FD19-V8 can weld even more smoothly and 15% faster than other robots in its class thanks to integrated supply lines, making it ideal for maximum productivity. It's equipped for all welding tasks and payloads up to 8 kg. The FD19-B6 offers an extended degree of freedom, allowing constant torch orientation when entering tight workspaces and is equipped for a payload of up to 6 kg. For our customer, the FD19-B6 has proven to be ideal. Of course, other welding processes and applications are also possible with this concept.

Seamless Integration in Record Time

One of the standout features of the Cube is its portability. This allows for a quick setup time of only 1-2 days on-site, including commissioning. This means our customers can transition to this innovative system without significantly disrupting their operations. In June 2023, we shipped the system from our headquarters in Mönchengladbach, Germany, and it has since impressed our customers.

This project underscores our commitment to innovative solutions that meet evolving customer demands. We would like to thank our partners for their trust and collaboration on this journey. At OTC, we strive to push the boundaries of technology and offer manufacturing solutions that boost productivity. Join us in transforming industries with our innovative approach!

Also, check out our YouTube video on this project: