Maximized spatter reduction by minimized heat input!

NEW SYNCHROFEED EVOLUTION

2023 Market launch of SynchroFeed Evolution

Discover our further improved SynchroFeed robot welding equipment. SynchroFeed Evolution features an improved compatibility to OTC DAIHEN welding power sources and a scalable setup of buffer and feeder combinations to fit best for your application without material limitations.

What is Synchrofeed?

Our OTC SynchroFeed process is a noteable improvement over conventional MIG/MAG welding processes. This is our welding solution to join medium and thin materials without deformation, account for gap tolerance, and significantly reduce welding spatter - all while being performed quickly and cost-effectively.

SynchroFeed utilizes precise wire guide synchronization principles to eliminate welding spatter. It works by retracting the wire at extremely high frequency of 100 Hz so that the droplet is directly dipped into the melt. The wire withdrawal from the melt is synchronized to ensure that no adhesion occurs, avoiding separation above the melt that causes spatter. The wire feed plays a decisive role in this process, and its withdrawal from the melt must be perfectly synchronized. This process cannot be achieved with commercially available push-pull systems. Through the high-dynamic control process, a larger amount of wire can be fed, resulting in an increase in melting deposit in the transitional arc area and a significant increase in welding speed.

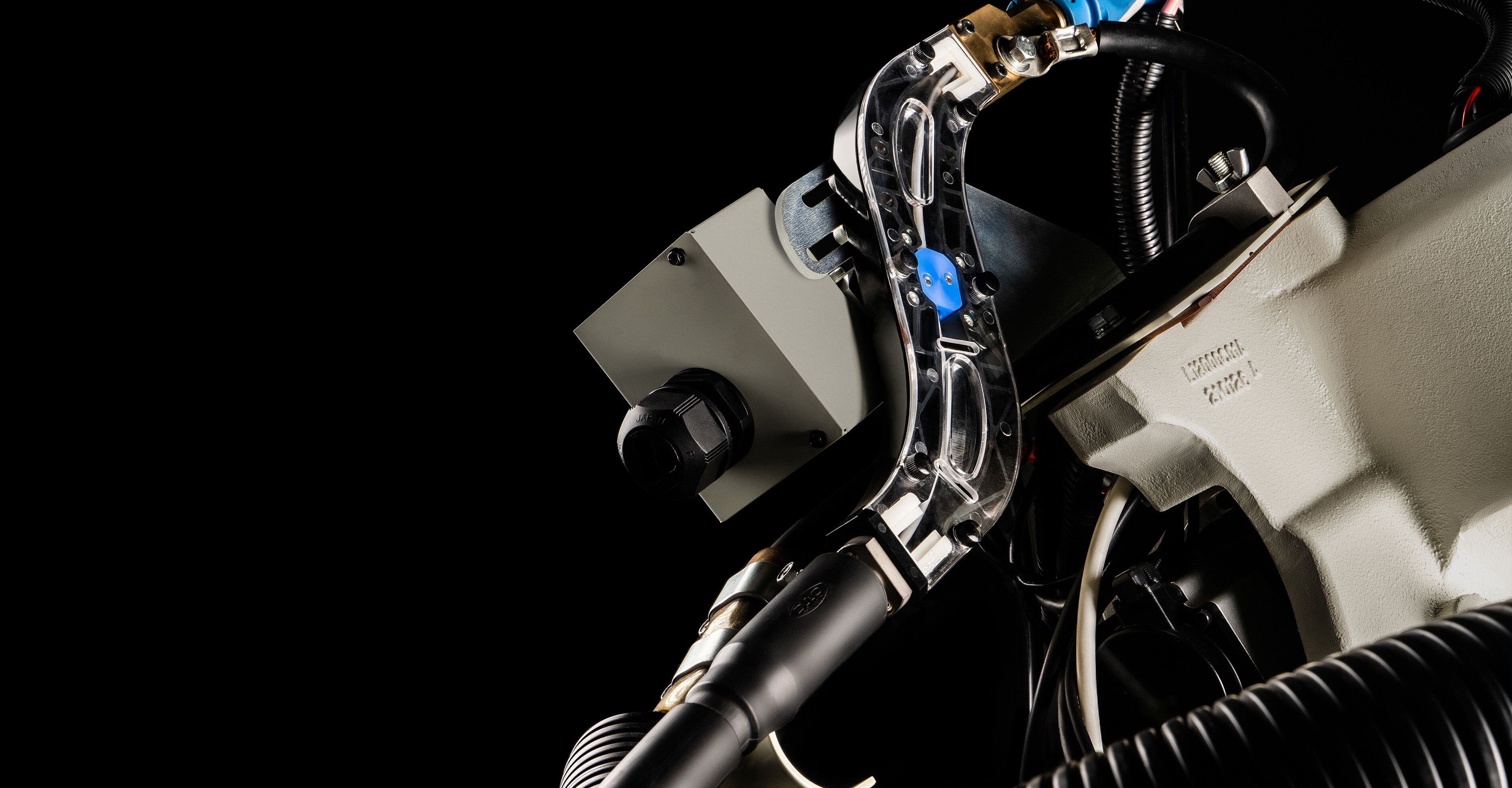

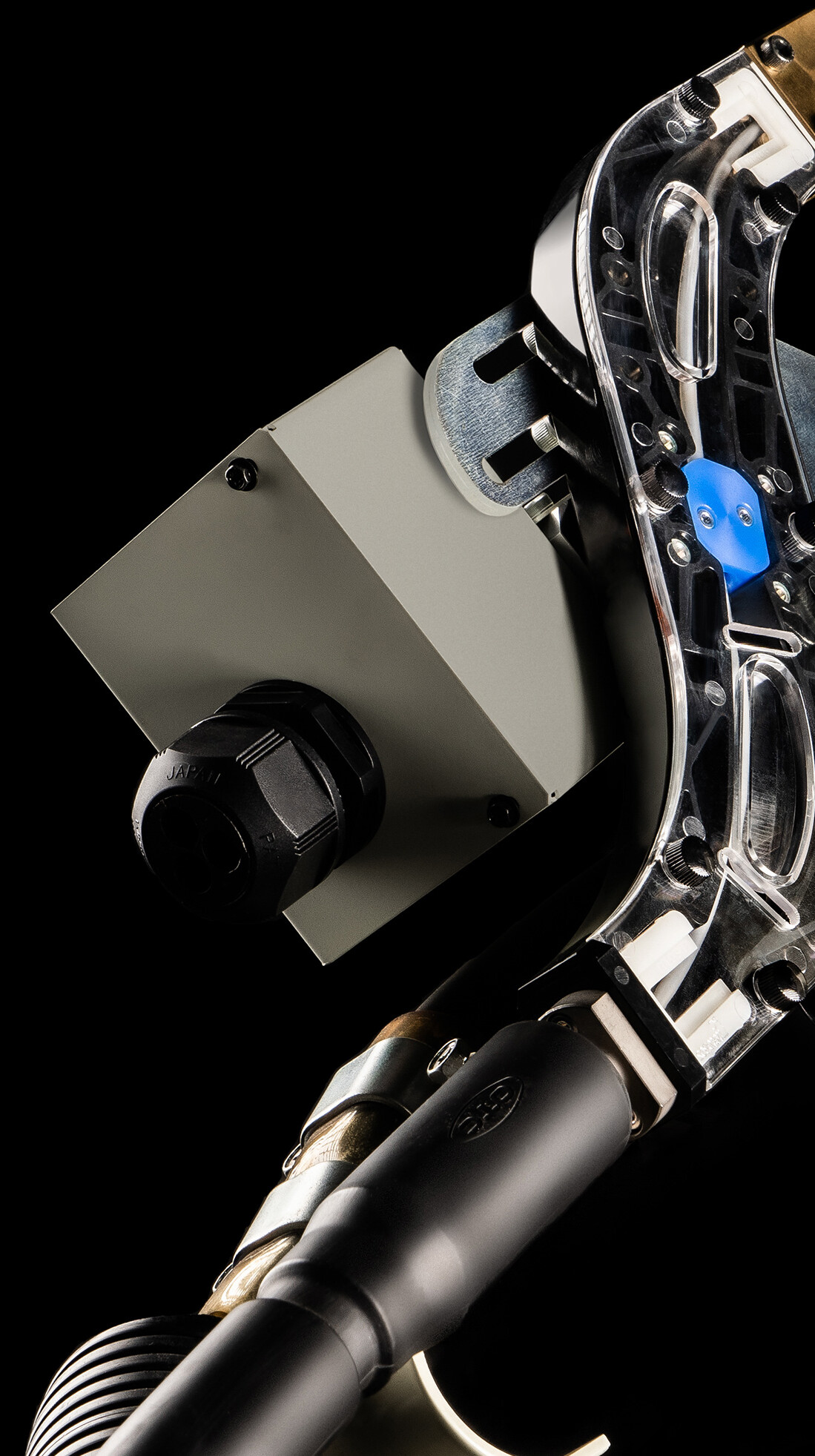

The SynchroFeed system includes two wire feeders, one push feeder on the wire barrel, a push/pull feeder at the torch mount and a "S"-shaped wire buffer on the third axis of the robot to ensure the wire to expand in the middle without encountering resistance or friction.

These two motors are precise synchronized and controlled by the Welbee chipset in our Arxis welding power sources. This setup allows the peak dip transfer (PDT) process, a controlled droplet transition in the short circuit phase. The PDT process is a precisely controlled short arc, which is only possible with the use of our fast Welbee processor.

Advantages of SynchroFeed :

- High weld deposition combined with low heat input

- Consistent and predictable penetration adopted to the welding speed

- Reliable connection between base material and weld, blowhole free

- Low distortion due to low and stable heat input

- Reduced costs due reduced post-weld cleaning and finishing

What makes SynchroFeed Evolution special ?

SynchroFeed Evolution offers software and hardware improvements:

Simultaneous robot welding

A new controlling software to support simultaneous welding with multiple robots on one work piece.

Compact pull torch

A new design pull torch with integrated cleaning feature and easy installation

Welding power source selection

An extended OTC DAIHEN welding power source selection from 400-500 Amp DC and 400A AC/DC offer a greater variety of processes such as AC MIG, Push Arc and SychroFeed Pulse.

Scalable Setup

SynchroFeed Evolution is available as LITE configuration for better price performance application and as PRO configuration for free material choice.

- Multiple usage of power sources: P402L, P502L, W400, ARXIS WB-P503L/ WB-P403L

- Combination of SynchroFeed with AC/MIG

- Suitable for aluminum alloys, mild steel and stainless steel

- Basic version of SynchroFeed

- Upgrade to SynchroFeed Pro possible

- Developed for mild steel and stainless steel in combination with wire drum

Discover more