Achieve deep penetration, clean welds and precise weld bead!

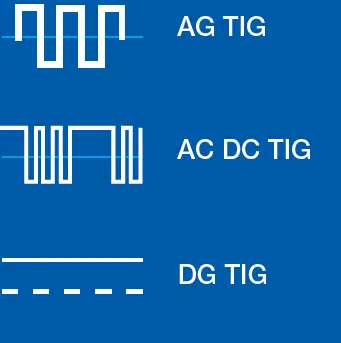

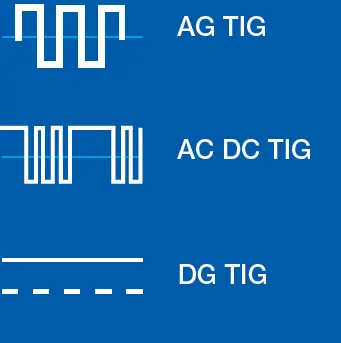

Our versatile TIG welding processes

TIG welding by OTC DAIHEN, is a highly versatile and precise welding process that offers numerous advantages for a wide range of materials. Whether it's aluminum, steel, stainless steel, or other metals, TIG welding provides exceptional control and produces high-quality welds. By utilizing different current types, such as AC and DC, OTC TIG welding offers specific benefits tailored to different material types. With its ability to achieve deep penetration, clean welds and precise weld bead formation, TIG welding is a preferred choice in various industries where superior weld quality and accuracy are paramount.

AC TIG Welding

Typically used for aluminium welding, AC TIG welding utilizes alternating current to weld. The energy released during the process helps to break down the oxide layer on the surface of the metal (cleaning effect). In the subsequent negative phase, the exposed base material can be melted, allowing for proper fusion.

AC/DC TIG Welding

AC/DC TIG welding combines both AC and DC pulses. The hybrid pulse mode is particularly effective for welding thicker aluminum materials. This method offers several advantages, including deep penetration without the need for preheating, extended electrode life, and precise weld bead formation, especially when using cold wire.

DC TIG Welding

DC TIG welding is used for materials such as steel, stainless steel, copper, copper alloys, and titanium. It relies on direct current (DC) to create the welding arc. Argon shielding gas is separately supplied to protect the welding zone and the arc.

Standard

Rectangular pulse shape, in which the peak value of both polarities is equal. The welding operations can be carried out in a wide range of sheet thicknesses. Since a stable welding result can be achieved over the entire current bandwidth, this is the most used waveform.

Hard

Rectangular pulse shape in which the peak value of the polarities is different. Due to the concentrated arc in DC/TIG welding, the penetration depth increases. This makes this mode particularly suitable for fillet welds or the first layer in multilayer welding. Of the three modes, electrode wear is the lowest, but the arc noise is the loudest.

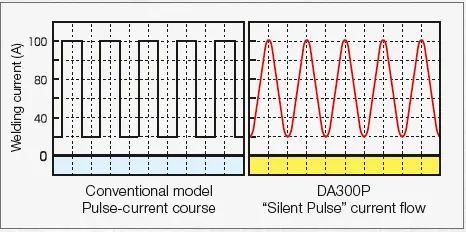

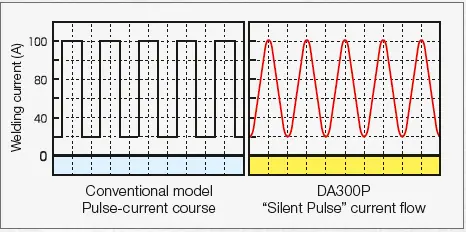

Soft - Silent Arc

Sinusoidal pulse shape in which the peak value of both polarities is equal. This produces a soft arc which is particularly suitable for thin sheets and butt welds. The arc sound is the quietest and the maximum welding current is 200A. The noise level is drastically reduced due to the sinusoidal current flow which realizes a controlled heat input.

Safe arc start:

The arc start is ensured by an optimized start current control and a powerful HF ignition unit which offers the following advantages:

- Safe arc start even when using longer hose assemblies

- Avoidance of ignition problems with multilayer welds

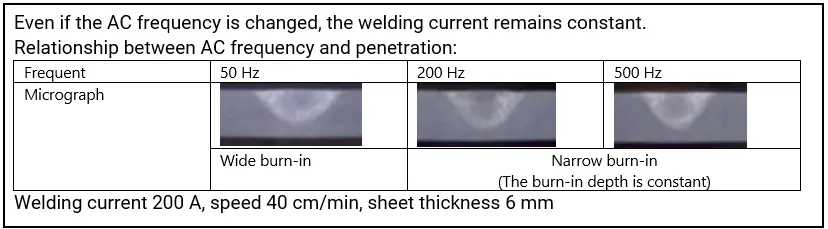

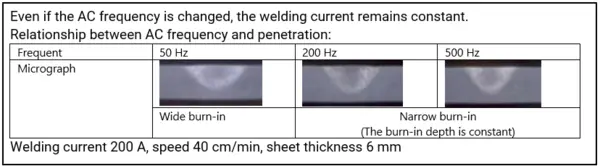

Constant welding current due to modified AC frequency

Due to the variable AC frequency, a different penetration can be generated. The penetration becomes narrower and deeper when the AC frequency is increased:

Advantages of tehe TIG welding process:

- Deep penetration without preheating

- More precise formation of seam scaling (with cold wire)

- Particularly suitable for thin sheets and butt welds

- Highly effi cient with thicker aluminum materials

- Safe and stable arc start

- Low noise level due to sinusoidal current and controlled heat input

Fitting your needs