Precise welding also for thick material!

Our Plasma Welding processes

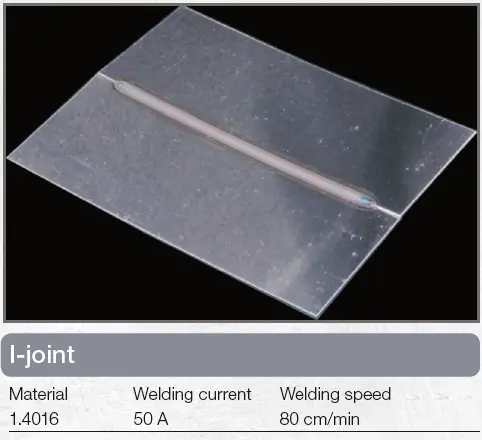

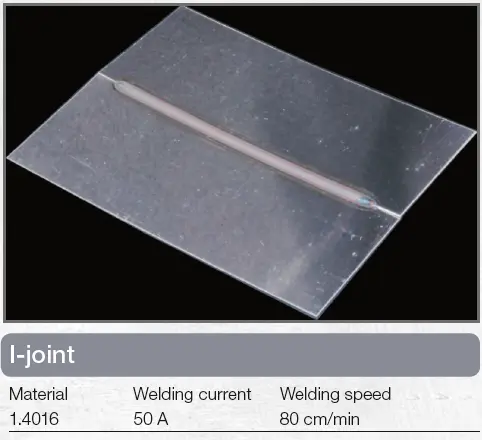

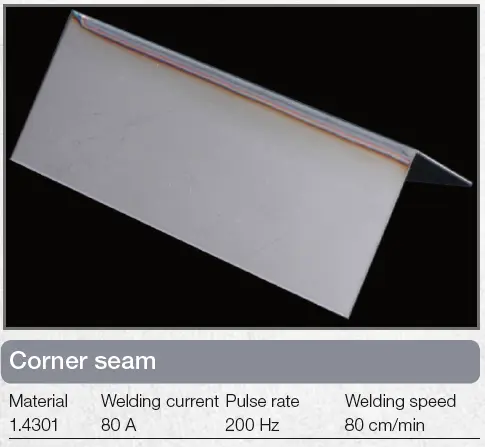

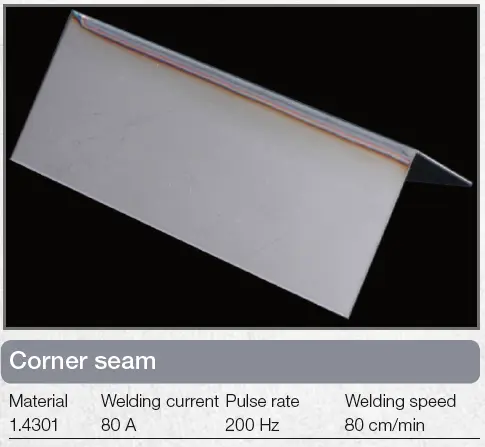

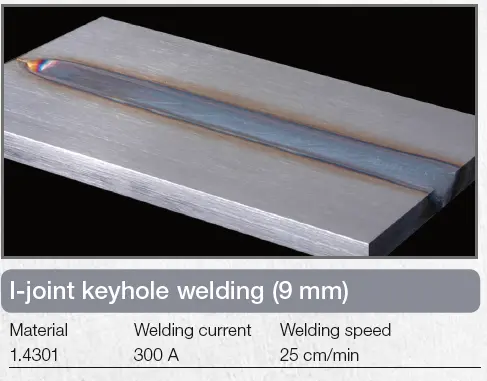

Plasma welding is particularly beneficial in applications where high welding speeds, deep penetration, and minimal heat-affected zones are required. It is commonly used in industries such as aerospace, automotive, and manufacturing, where precise and high-quality welds are crucial. By enabling keyhole welds and offering better control over the welding process, plasma welding by OTC provides an advanced solution for achieving accurate and reliable welds in thin and thick materials.

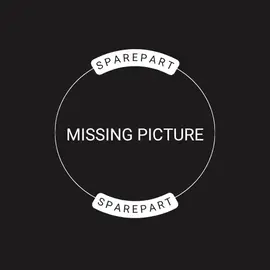

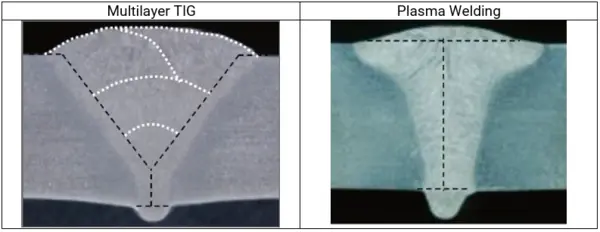

Multilayer TIG vs. Plasma Welding

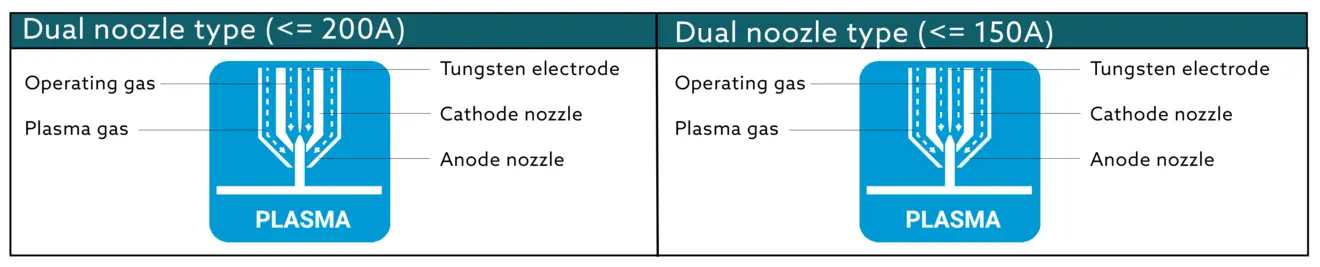

During plasma welding, an electric arc is established between the tungsten electrode and the workpiece. The arc passes through a copper nozzle, which constricts and shapes the plasma gas flow. The plasma gas, typically argon or a mixture of argon and hydrogen, is introduced through the nozzle to create a highly concentrated and stable arc.

Key advantage OTC plasma welding with pilotgas

The key advantage of plasma welding is its ability to achieve deep penetration and narrow welds, known as keyhole welds. The intense heat generated by the plasma arc creates a keyhole or narrow cavity in the molten pool, allowing for efficient fusion between the base metal and filler material. This results in strong and precise welds in thin and thick materials.

High-Speed welding pattern

Fitting your needs