Modern Offline Programming Software for Robotic Cells!

OTC ADVANCED:

Efficient Offline Programming for Optimal Welding Processes

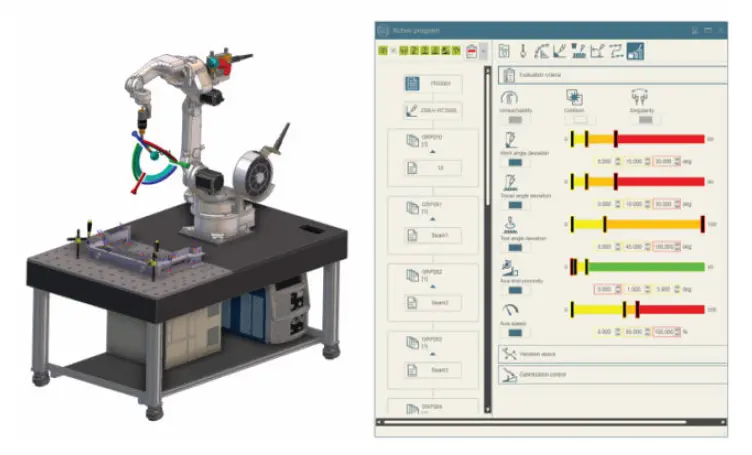

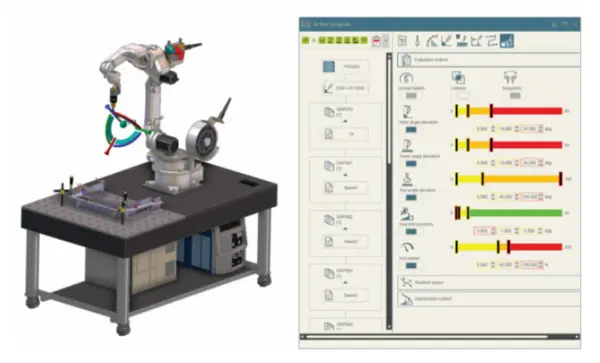

With OTC ADVANCED, OTC DAIHEN EUROPE GmbH offers a powerful CAD-based offline programming solution specifically designed for the programming and simulation of robotic systems. Unlike traditional teach-online programming, OTC ADVANCED enables comprehensive reachability and feasibility studies to efficiently optimize robot layouts and ensure the best possible performance in any production environment.

The software features a user-friendly interface, allowing users without extensive programming knowledge to quickly and accurately create and test robot programs before seamlessly integrating them into the production line.

A key highlight is the fixture builder, which enables easy and flexible design of welding fixtures, significantly improving precision and reliability in production workflows. Additionally, the automatic optimization of welding parameters ensures that programs run flawlessly and efficiently at all times.

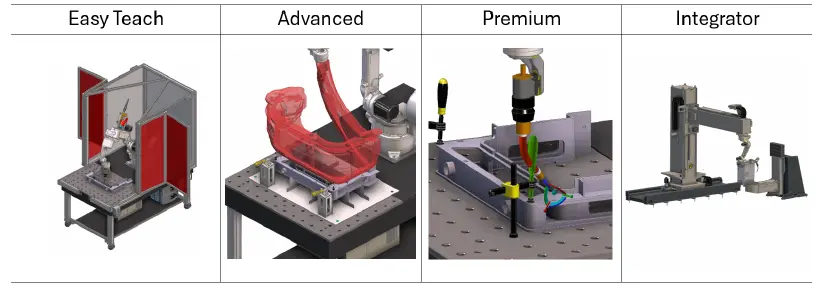

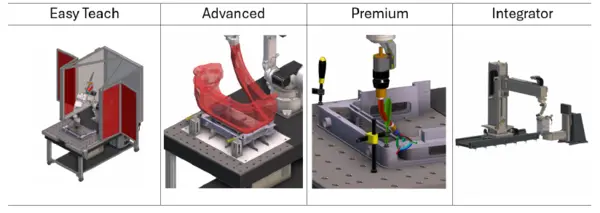

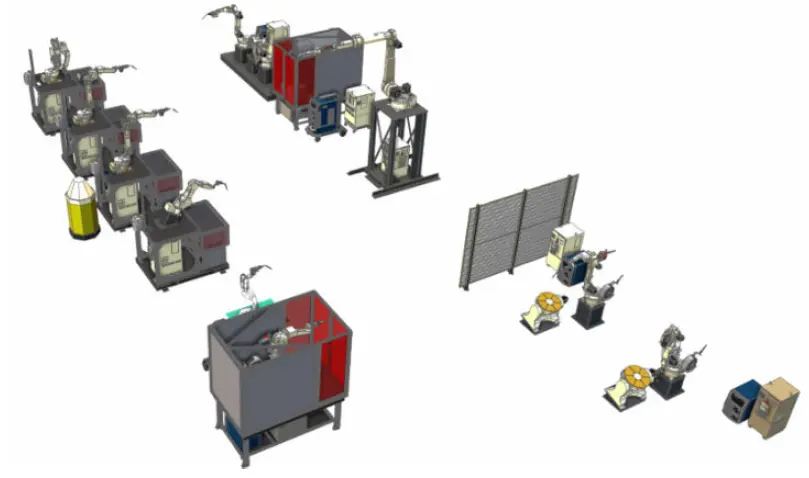

OTC ADVANCED is available in four different packages tailored to the diverse needs of users: EasyTeach, Advanced, Premium, and Integrator.

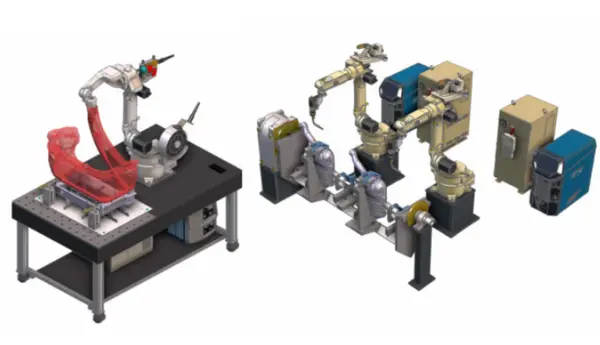

- The EasyTeach package offers ready-to-use robotic cells, CAD integration, and advanced arc welding strategies for quick results.

- The Advanced package provides benefits such as advanced welding volume analysis and twin-robot cell synchronization.

- The Premium package takes efficiency to the next level with automatic path and linkage optimization

- Finally, the Integrator package allows flexible layout creation and access to a personalized resource library to meet specific project requirements.

By combining powerful features with versatile application packages, OTC ADVANCED delivers a comprehensive solution for optimizing offline programming and welding processes—significantly enhancing both planning reliability and manufacturing productivity.

OTC Advanced offers 4 different packages

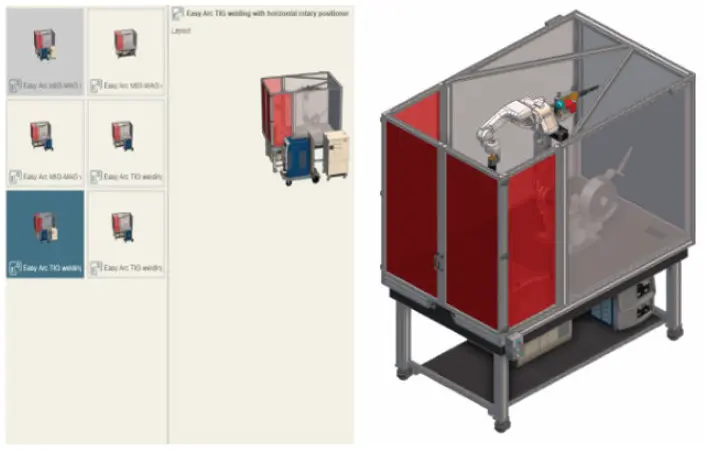

Easy Teach Package

- Ready-to-Use Robot Cells: Get started instantly with preconfigured EasyARC virtual robot cells.

- CAD Integration: Import CAD data to create workpieces.

- Advanced Arc Welding Strategies: ofÒine programming solution with built-in arc welding technology strategies for

superior results. - Simulation & Validation: Visualize and detect collisions before they happen with comprehensive simulation and

collision detection tools. - Download Programs: Download and deploy your robot programs directly to the production line without causing any

interruption.

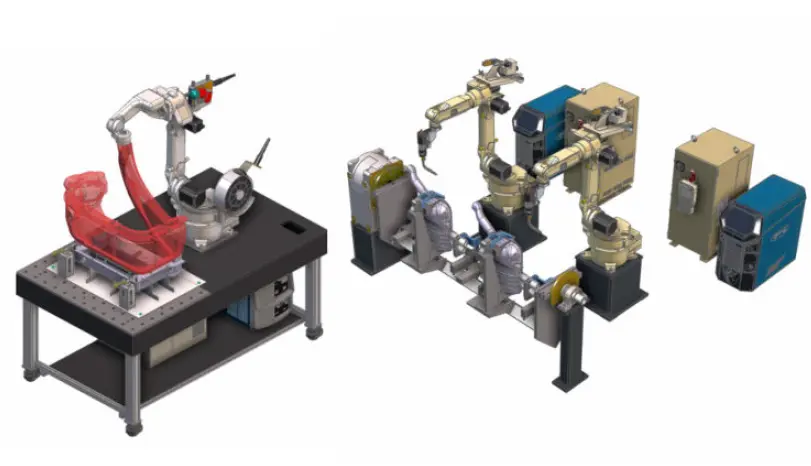

Advanced Package

- Fixture Builder: Design and customize fixtures with precision using a powerful, intuitive fixture builder.

- Swept Volume Analysis: Optimize your robot’s movements and workspace with advanced swept volume analysis,

ensuring efÏcient and collision-free operations. - Twin Robot Cells: Maximize productivity with twin robot cells, allowing for synchronized or parallel operations with

multiple robots. - Versatile Technology Integration: Expand your capabilities with seamless access to additional technology

packages, including spot welding, sealing, laser cutting, laser welding, deburring, painting, and more.

Premium Package

- Automated Path Optimization: Achieve peak efÏciency with intelligent, automatic path optimization, ensuring your

robots follow the most efÏcient routes. - Path Linking Optimization: Experience effortless workflow continuity with automatic linking path generation,

enabling smooth transitions between welding operations.

Integrator Package

- Custom Resource Library: Build and manage a personalized resource library, adapted to your specific project

needs and preferences. - Flexible Layout Creation: Design and configure layouts, allowing you to adapt and optimize your production

environment effortlessly.

Synergies Between WeldUniverse PRO and OTC ADVANCED: Efficiency Enhancement Through Seamless Integration

The combination of WeldUniverse PRO and OTC ADVANCED creates a powerful synergy that helps companies comprehensively optimize their welding processes and increase efficiency. While WeldUniverse PRO ensures real-time documentation and analysis of welding parameters, OTC ADVANCED enables precise offline programming and simulation of robot movements.

This integration offers numerous advantages: Companies can develop and optimize welding programs virtually, ensuring they are error-free and efficient from the start. Once the programs are loaded into the production line, WeldUniverse PRO monitors processes in real time, providing valuable data for quality assurance and traceability.

By seamlessly connecting planning and execution, companies can minimize downtime, improve product quality, and enhance the efficiency of the entire production chain. Additionally, centralized process and resource management via the WeldUniverse PRO dashboard allows for in-depth analysis and optimization, while the flexible offline programming capabilities of OTC ADVANCED keep production flow agile and adaptable.

Overall, companies benefit from increased planning reliability, reduced costs, and greater competitiveness through the continuous digitalization and automation of their welding processes.