Ideal welding cobot for the shop floor

THE FIRST REAL WELDING COBOT

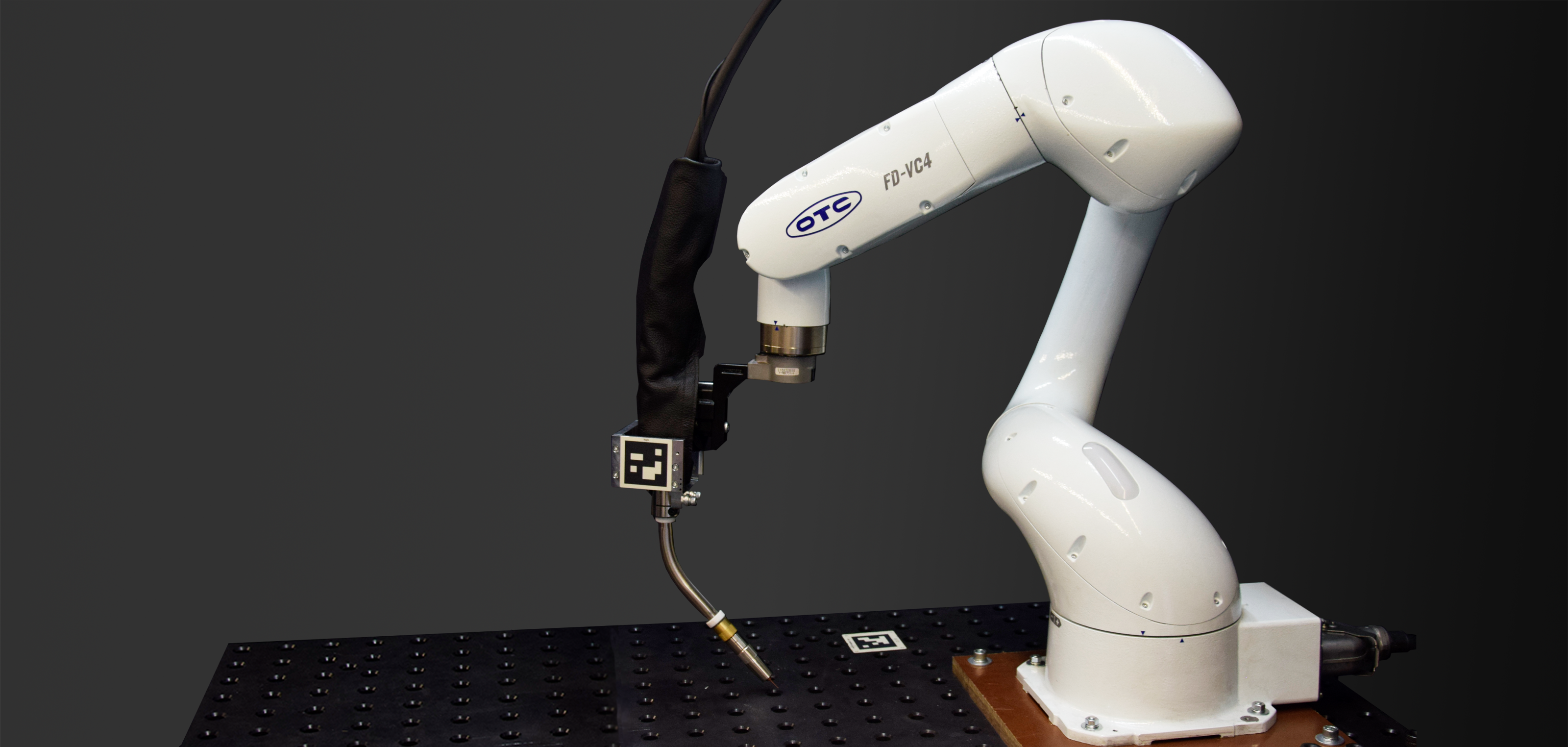

The OTC Cobot FD19-VC4 is compatible with the complete OTC welding technology and sensor portfolio and is the first Cobot specifically developed for welding applications.

This Cobot provides an easy entry into automation without extensive cobot training, thanks to the simple teach-in method developed by OTC DAIHEN EUROPE GmbH, experts in the field for years. In 1983, OTC pioneered the use of a teach pendant to program robots and welding equipment on a single device. In 2023, OTC continues this work with the first visual programming of robots and welding technology on a single device with PhotoTeach.

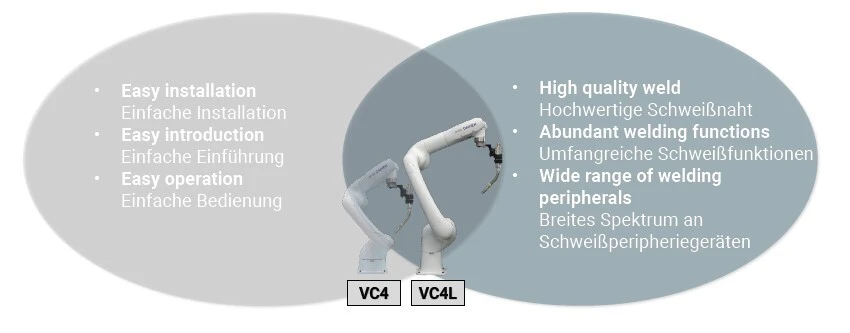

The OTC solution for the automation trend is the Cobot VC4, which does not require any equipment from the operator and is also a ready-to-weld Cobot with the following features:

- Spatter proof design

- User friendly programming / teaching

- For welding modified axis (high accuracy)

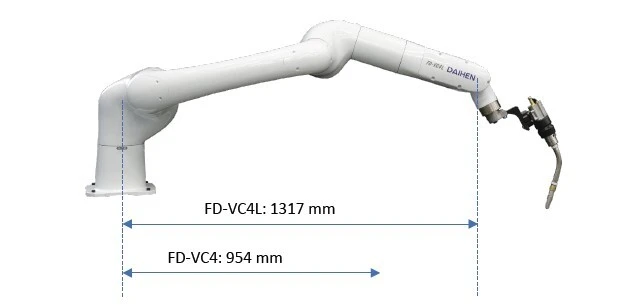

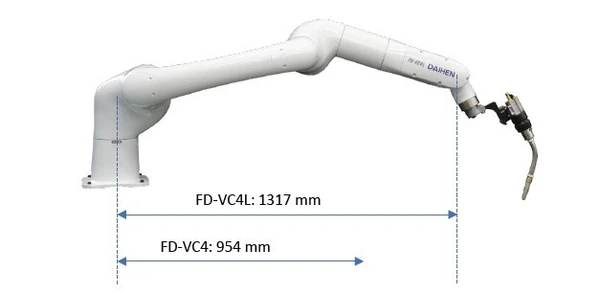

The first collaborative robot (Cobot) VC4 from OTC stands out for its ease of use and marked the introduction of our series of collaborative robots. With the long-arm Cobot VC4L, we offer excellent welding performance equivalent to that of industrial robots. Both models are functionally compatible and can be easily integrated into existing processes.

Compared to the VC4, the long-arm Cobot achieves a reach that is 1.4 times greater. The expanded motion range allows for diverse applications, such as multi-station setups. Despite its maximum reach, the robot remains in the same transportable class of collaborative robots.

Optimal welding robot for the shop floor

With its modern design and easy application, the Cobot is the optimal welding robot for the shop floor.

Function Features

1. High trajectory accuracy optimal for arc welding

Optimal for welding applications equivalent to industrial robots

2. High frequency resistance

Perfect for applications where high frequency noises are generated such as TIG welding.

3.High durability, dust- and spraywater protection

Conform to IP65 standard.

Cobot protection against heat radiation and spatter -> no covering required

4. Complete OTC welding portfolio applicable

Ready to use OTC industrial robot accessories such as standard welding equipment, SynchroFeed, ServoTorch, sensors etc.

Design Features

1. Collaborative Design without corners and edges

Floating Design without corners and no risk of crushing.

Minimized risk for injuries due to collision detection.

2. Lightweight, small-sized, easy to move

Compared to smallest OTC industrial robot H5 with 58 kg, our VC4 cobot has a weight of 37 kg -> 36% weight reduction

3. LED status indication

VC4 cobot working mode is displayed on the top of the second robot axis.

4. Complete cobot cabling inside the main unit

Wiring and air connection are accesible at the 5th axis

Discover more