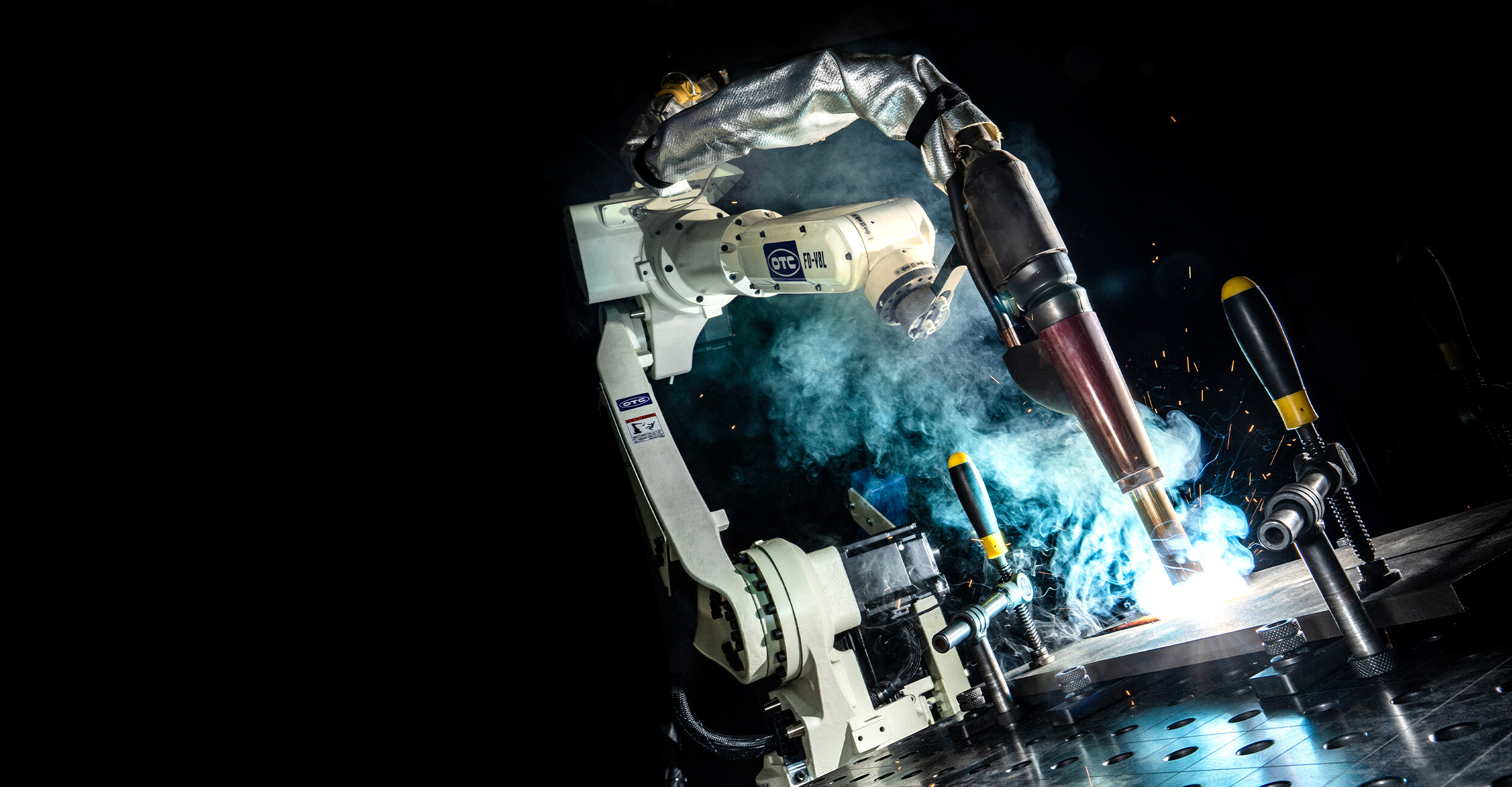

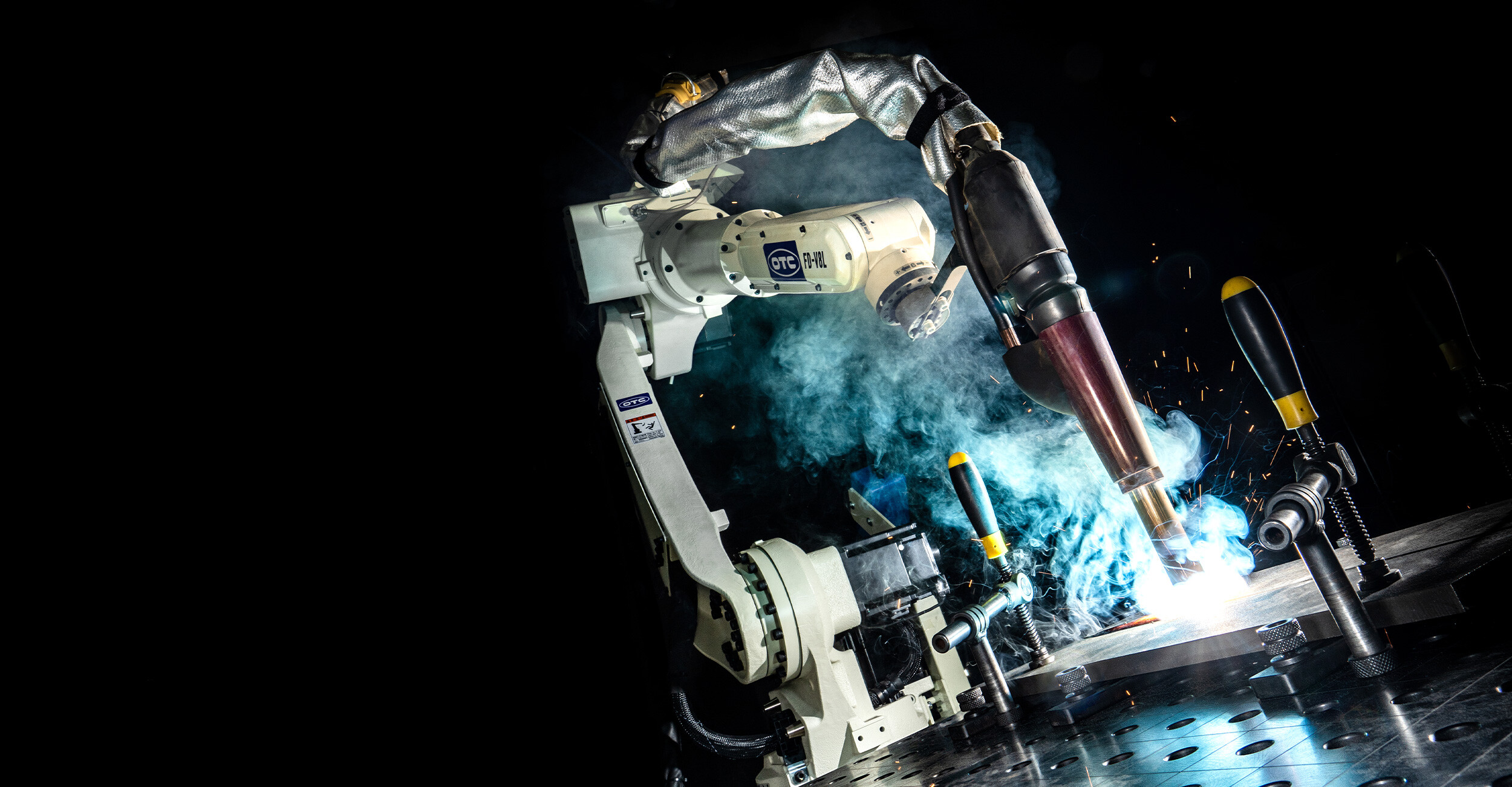

DISCOVER OUR MIG/MAG PROCESSES

Highly efficient thick sheet welding process

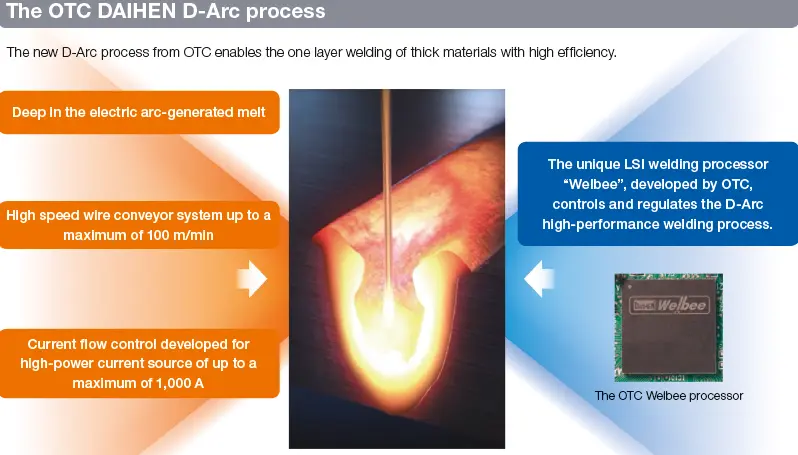

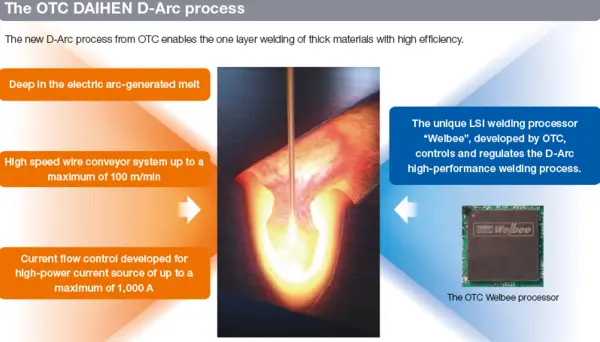

OTC's D-Arc Process is an innovative welding technique that allows for the efficient single-pass welding of thick plates. It represents a significant advancement in the field of thick-plate welding.

Advancement in Thick Plate Welding

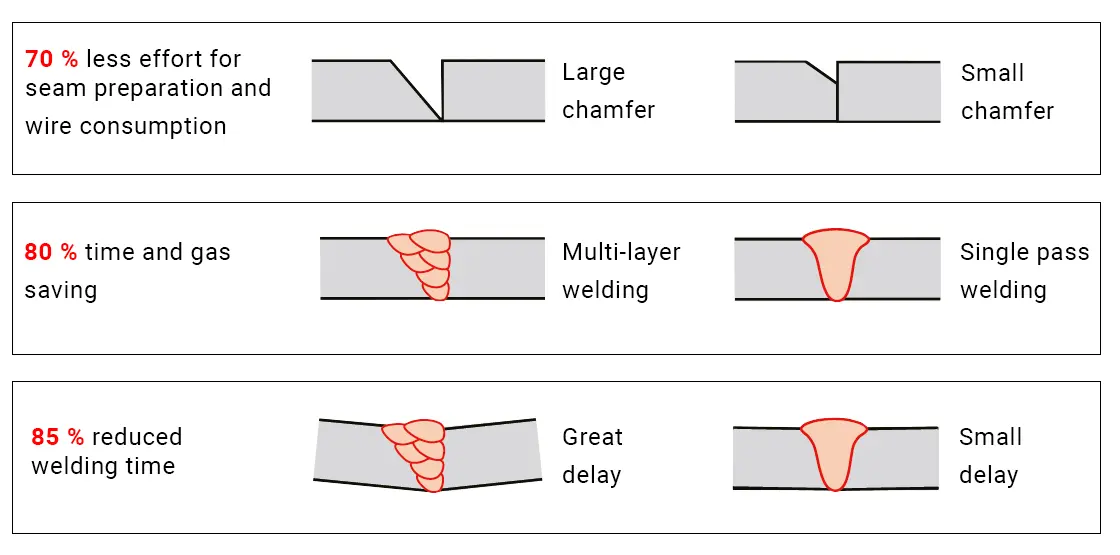

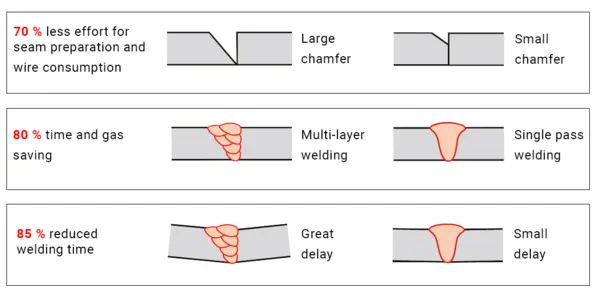

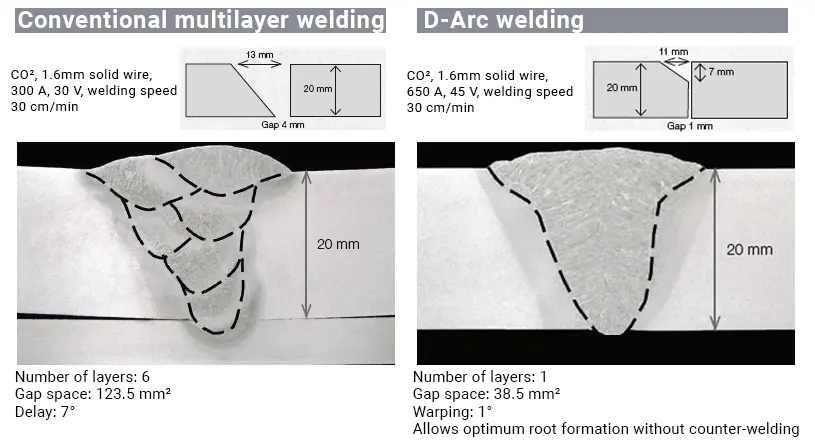

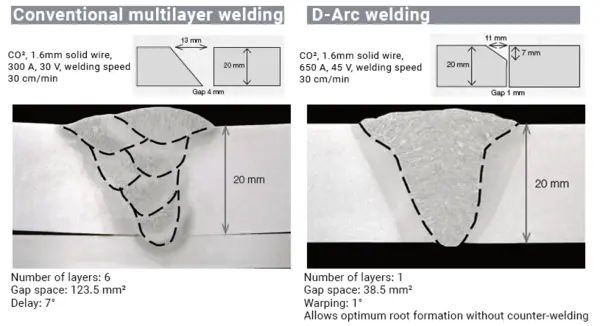

The D-Arc Process represents a significant advancement in the welding of thick plates. It utilizes a rotating and oscillating arc that generates a high level of material deposition while maintaining controlled heat input. This results in improved efficiency and reduced requirements for weld preparation, such as the need for extensive joint bevelling.

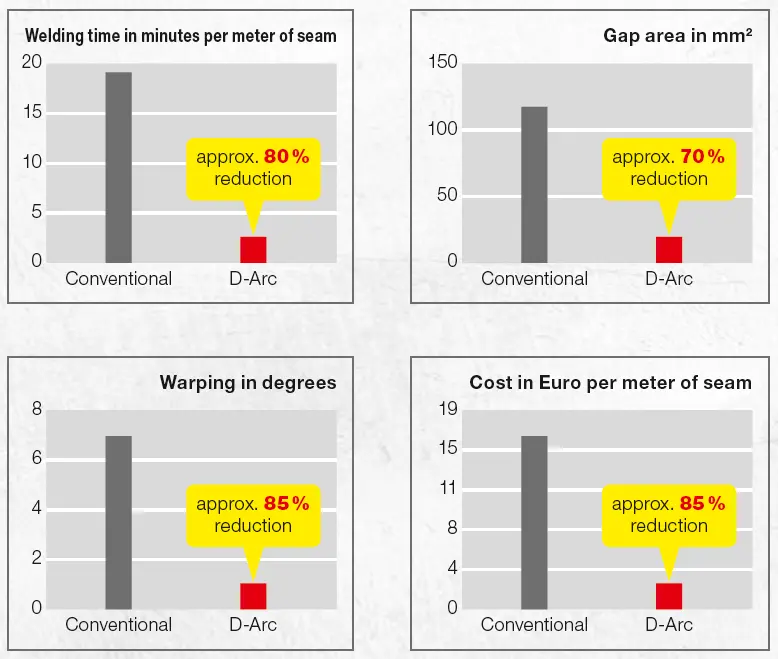

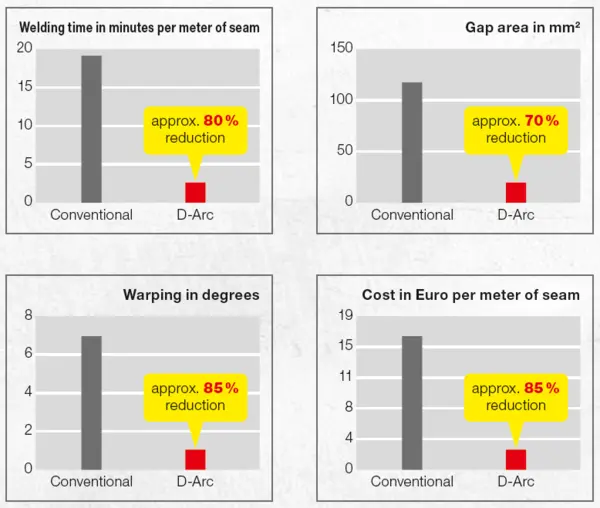

Replacement of Conventional Multi-Layer Welding

Unlike conventional multi-layer welding techniques, the D-Arc Process enables single-pass welding. This significantly reduces the process time, as there is no need for multiple layers of welding. By eliminating the time-consuming process of layer-by-layer welding, productivity is increased, and overall costs are reduced.

Optimal Root Formation

The D-Arc Process allows for optimal root formation without the need for back welding. The unique characteristics of the rotating and oscillating arc ensure that the root of the weld is well-formed and fused without requiring additional welding from the backside. This simplifies the welding process and improves the overall quality and integrity of the weld.

D-Arc Welding Pattern

The D-Arc Process follows a specific welding pattern that is designed to achieve optimal results. This pattern ensures proper penetration, uniform heat distribution, and reduced distortion. By adhering to the D-Arc welding pattern, welders can consistently produce high-quality welds with minimal defects and improved visual appearance.

Discover more