A further development of the pulse function to minimise porosity!

AC/DC wave pulse function for AC/MIG welding

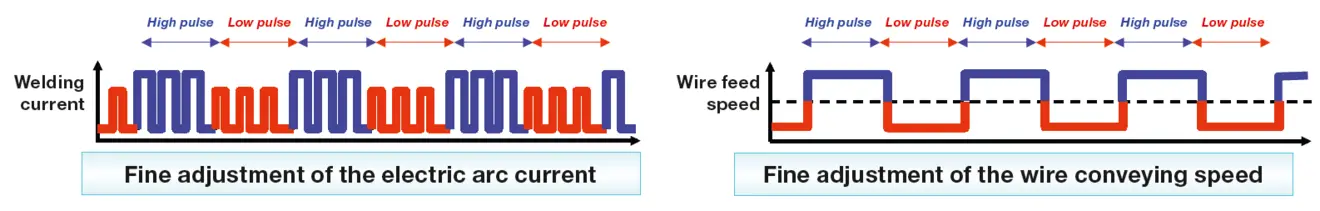

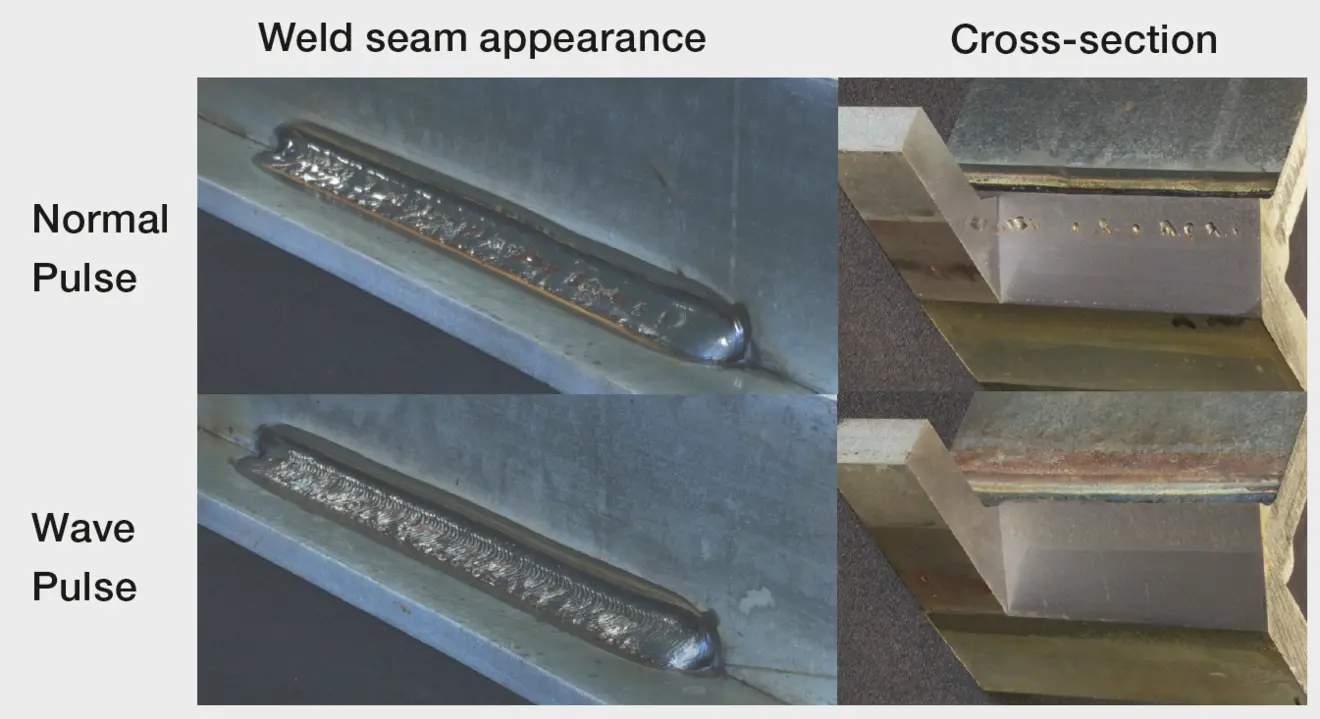

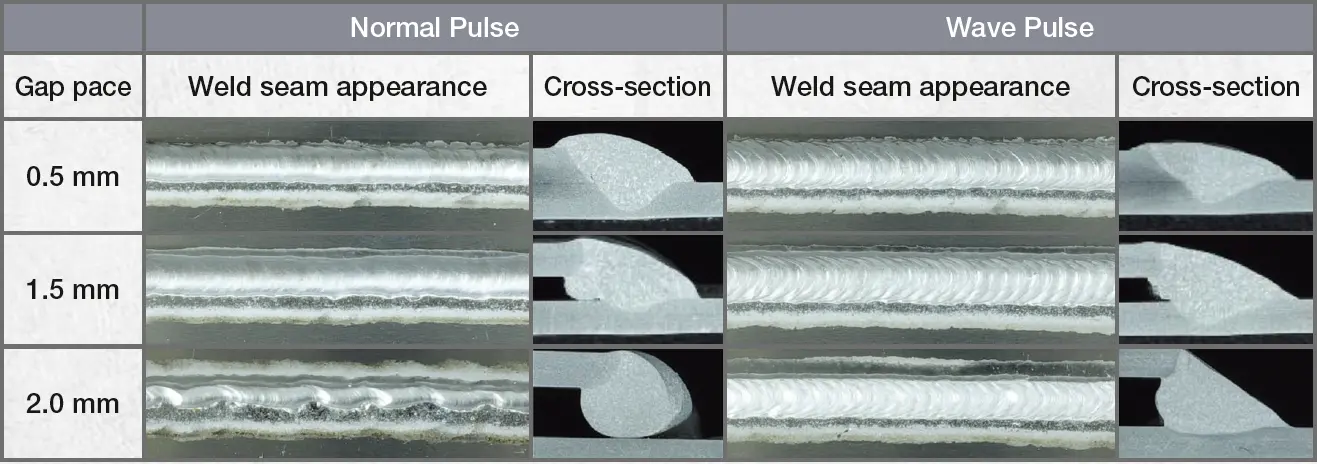

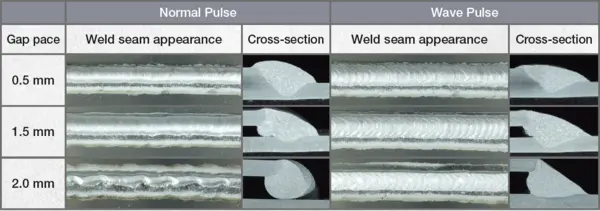

The Wave-Pulse function is a further development of OTC DAIHEN. Additionally to the current parameter, Wave Pulse has the option to set the correlation between high- and low-current phase and frequency of the pulse set. The OTC DAIHEN Welbee Welding Chipset aligns current and frequency with the feeding speed. The advantages of this function includes a reduction in porosity, improved gap bridging capability finalized by an excellent weld bead appearance.

Reduction of gas pores

In AC/DC Wave-Pulse welding, pores are reduced through the combination of AC, DC and the pulse function. The alternating current with different current peaks brings the weld pool into vibration which supports outgassing.

By combining the cleaning effect of AC and the controlled alternating heat input, AC/DC Wave-Pulse welding significantly reduces pore formation. The result is high-quality welds with improved integrity and a reduced risk of structural weaknesses associated with porosity.

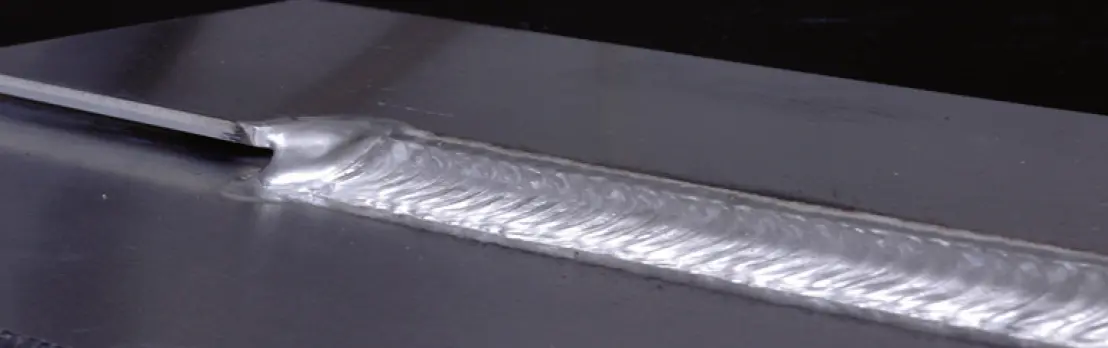

Excellent weld appearance

The OTC Wave-Pulse function can generate a weld appearance similar to TIG welding. This is achieved through precise heat control, reduced heat input, and uniform filler material distribution. These factors result in narrower, finer weld beads that resemble the aesthetic of TIG welding. This allows for greater control over the general welding process and the creation of high-quality welds with enhanced visual appeal.

Controlled heat input

The excellent gap bridging in welding using the OTC Wave-Pulse function is attributed to the controlled heat input. This controlled heat input allows for better penetration and fusion between the workpieces, even in the presence of small gaps. The precise management of heat ensures that the molten metal effectively fills the gaps and creates a strong and reliable bond. By carefully controlling the heat input, the OTC Wave-Pulse function enables welders to achieve exceptional gap bridging capabilities, resulting in high-quality welds with minimal discontinuities.

Discover more