Optimized weld geometry without under-cut

MIG/MAG Push-Arc

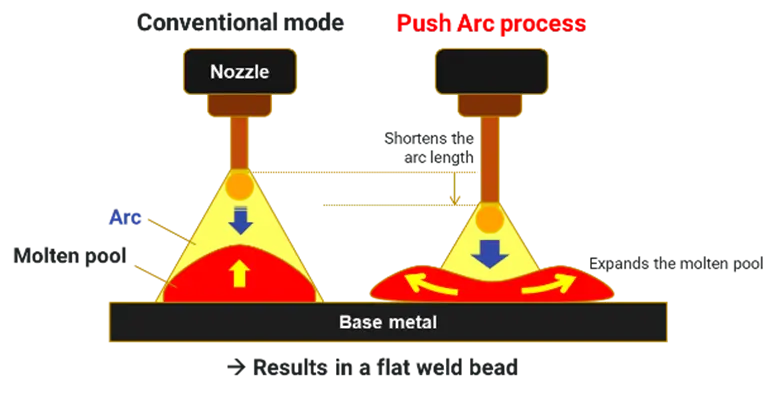

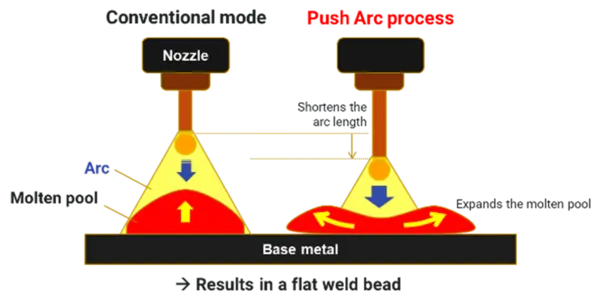

The push-arc welding process revolutionizes the field of MIG/MAG welding by introducing a new approach to drop transfer, employing electronic pulses for arc control. In push-arc welding, the length of the arc is shortened by applying and additional pulse, causing the molten pool to expand on the base metal. Due to the push effect, the reduction of under-cut is achieved as well as the welding wire is actively pushed into the molten pool. This ensures optimized weld geometry and process stability.

In the push-arc process, excess weld metal becomes lower in height

The time to release zinc gas mixed in is short.

Use arc force to expand the molten metal so that the bead can be flattened.

The molten metal shakes when it is expanded which facilitates the realease of gas mixed in.

For the push-arc process, feed frequency is high.

The increased number of times the molten metal is shaken makes it easy to release gas mixed in.

Discover more