Discover our MIG/MAG Processes

Realtime Penetration control

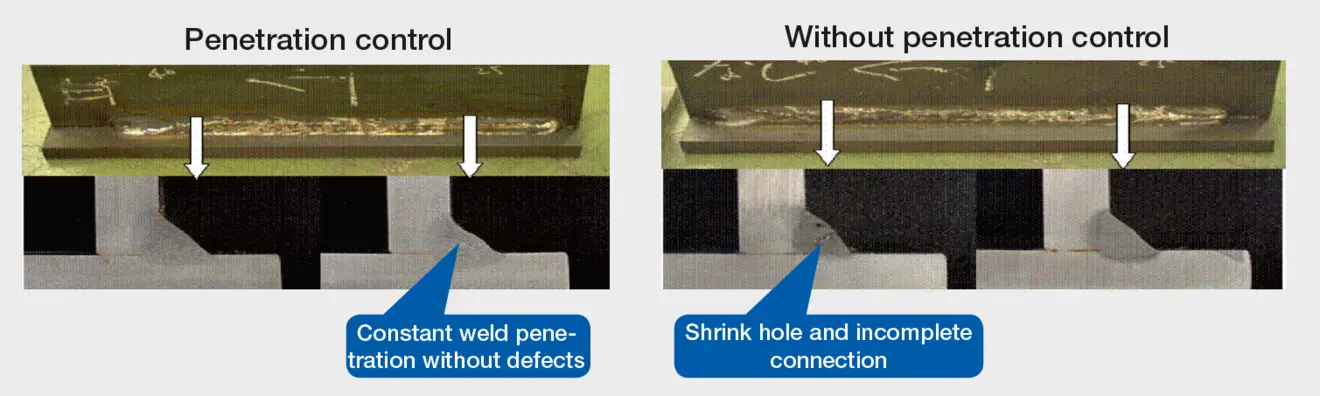

OTC DAIHEN welding power sources offer the option to adjust the wire feed speed to maintain a constant welding current automatically even when the stick out varies. The welding parameters such as the voltage, current, travel speed, and heat input are important to control to realize a welding penetration control.

Increasing the welding current or decreasing the travel speed can increase the depth of penetration. It is important to control penetration in welding to ensure the desired mechanical properties and quality of the welded joint.

Advantages of penetration control:

- Easy achiving of stable and reproducible penetration adopted to the welding speed

- Reliable connection between base material and welding seam

- Low distortion due to lowest and stable heat input

- Reduced costs due to less post-weld cleaning and finishing after welding

Discover more