Essential tools for next level welding

OUR WIRE FEEDER PORTFOLIO

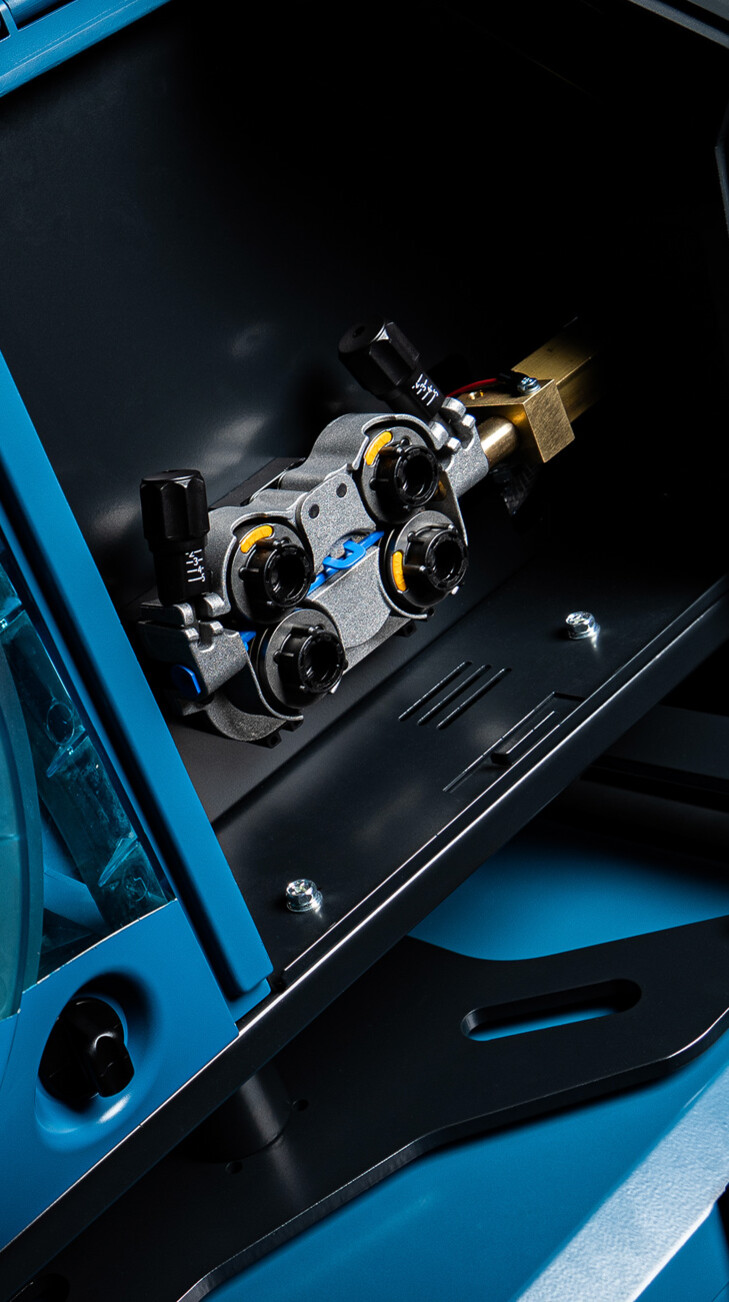

Wire feeders are used to supply filler metal to the weld joint and are essential for MIG/MAG and TIG cold wire welding. External wire feeder can provide significant advantages over internal wire feeders and are a popular choice for professional welders looking to improve the quality and efficiency of their welding process.

Advantages of external wire feeders

Improved maneuverability: Using an external wire feeder allows you to move the wire feeder unit separately from the welding machine, providing greater maneuverability and flexibility during the welding process.

Remote control: Many external wire feeders come with remote control options, which allow the operator to adjust the wire feed speed and other parameters without having to stop the welding process, saving time, and improving productivity.

Increased productivity: External wire feeders can typically handle larger spools of welding wire than internal wire feeders on welding machines, which means less downtime spent changing spools and more time spent welding.

Consistent wire feed: External wire feeders can provide a more consistent and steady feed rate of welding wire, leading to better quality welding results and reducing the risk of defects or inconsistencies in the weld.

Remote control: Many external wire feeders come with remote control options, which allow the operator to adjust the wire feed speed and other parameters without having to stop the welding process, saving time, and improving productivity.

Discover more