PTS Prototypenteile und System Technik GmbH

Expansion into New Markets with EASY ARC Welding Robot Cell

Company Background

Since 2006, PTS GmbH has been developing and producing vehicle components and specialized parts for demanding applications such as exhaust systems for cars and commercial vehicles. The client list includes renowned vehicle manufacturers as well as large suppliers from Southern Germany. In close partnership, PTS supports its customers in realizing innovative components for prototypes and small series.

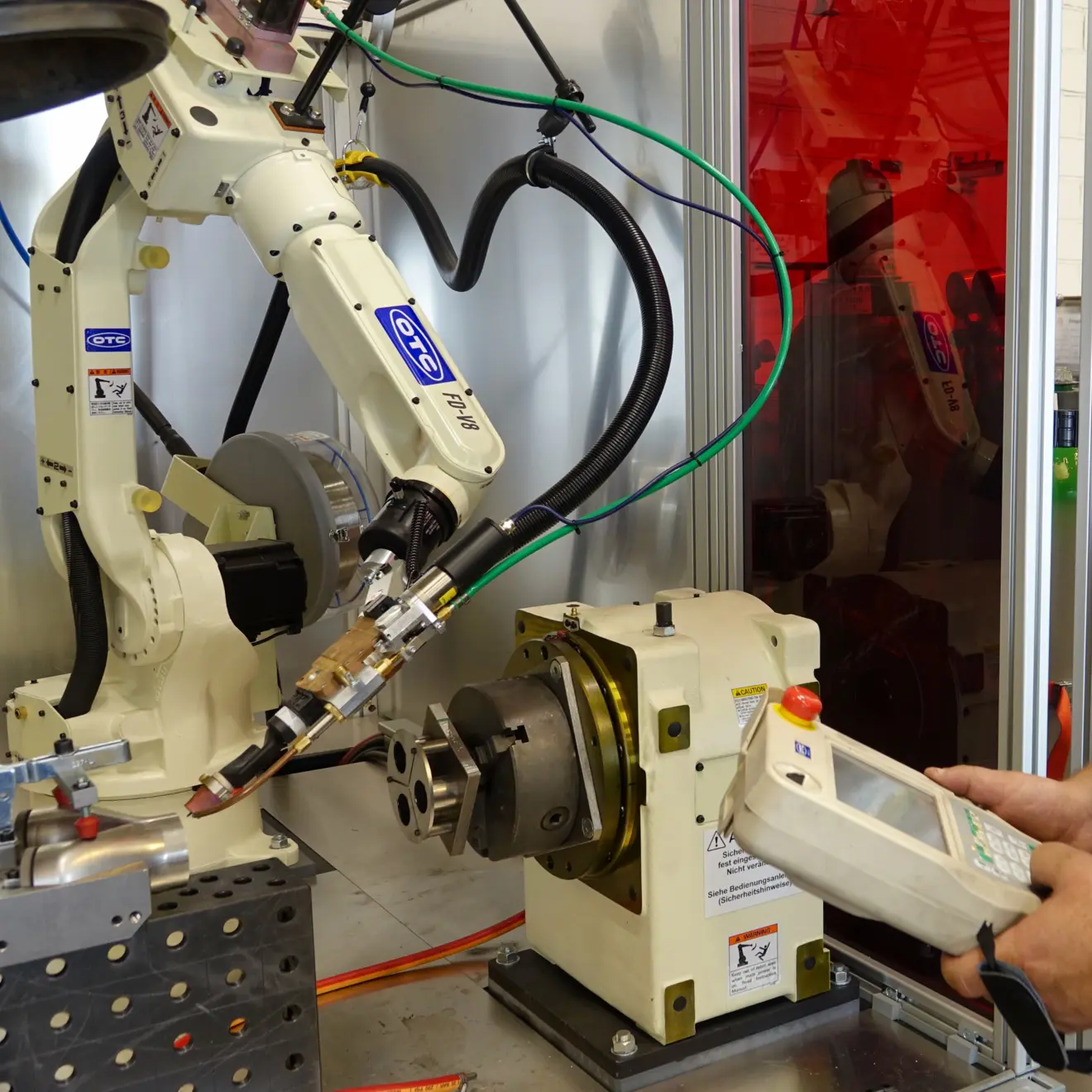

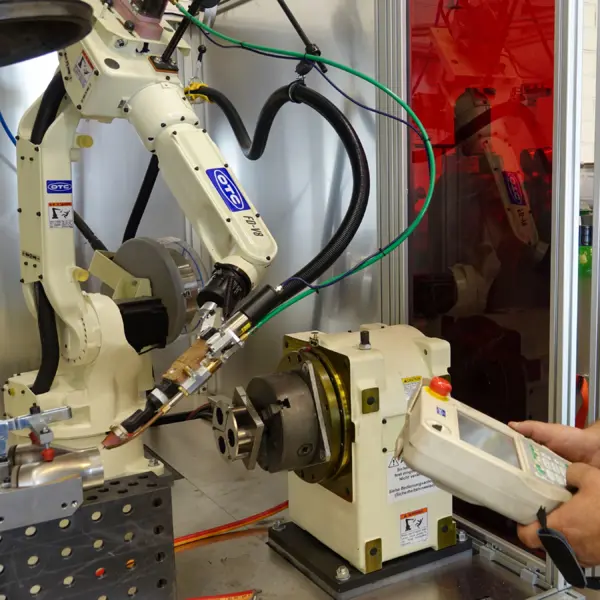

The EASY ARC Robotic Welding Cell: Precision and Flexibility for PTS

For years, PTS has been using the compact EASY ARC welding cell from OTC, which has not only expanded their production capacities but also opened up new markets, such as furnace construction. The robotic cell enables high welding quality and flexibility—crucial advantages that helped PTS secure a new major customer.

Technical Details of the Welding Cell:

- Robot: 6-axis welding robot, model FD-V8

- Positioner: Horizontal rotary positioner for maximum flexibility

- Welding Technology: TIG welding process with water-cooled welding machine, model DA300P

- Control: Synchromotion software and Easy Teach control for easy programming

- Safety: Standardized enclosure for optimal safety

Process Optimization with the EASY ARC Welding Cell

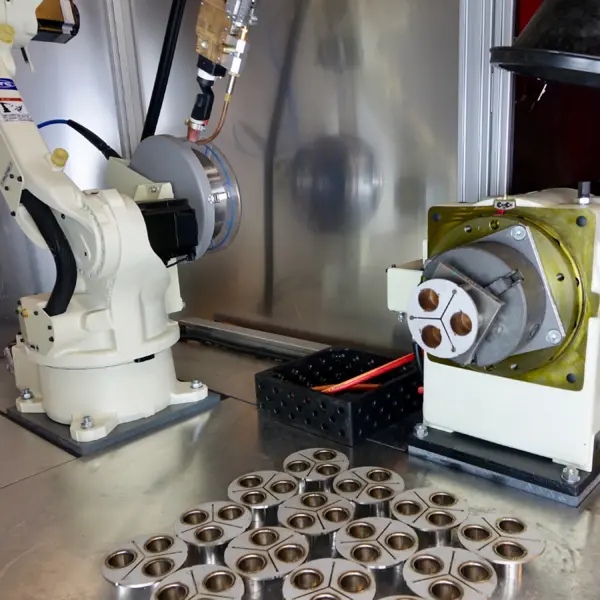

With the EASY ARC cell, PTS was able to significantly improve welding quality, especially for heat-resistant materials like austenitic stainless steel. The automated TIG technology nearly eliminates welding spatter and achieves exceptionally high microstructure quality of the weld seams—a decisive factor for PTS’s serial production.

Advantages for PTS: New Business Fields and Faster Production Cycles:

- Production Flexibility: The simple programming and quick tool changes allowed PTS to adapt flexibly to specific requirements and customer requests. By using the grid measure, PTS seamlessly integrated all fixtures.

- Quality Assurance: The first small series in furnace construction (800–1,000 pieces) confirmed the outstanding welding quality. The lifespan of the component made with EASY ARC increased by 3 to 4 times.

- Expansion of Customer Base: The robotic cell opened up new markets for PTS. Successful production of demanding parts earned the trust of a new customer and secured follow-up orders for PTS.

Implementation and Training

The introduction of the EASY ARC welding cell went smoothly: thanks to the OTC training, employees were ready to use the system after a short training phase and were able to successfully implement their projects. The quick integration and ease of use of the cell perfectly matched PTS’s proven production methodology, which demands maximum flexibility and short cycle times.

Conclusion

The EASY ARC welding cell not only enabled PTS to increase production quality but also gave them a crucial competitive edge. With the new welding cell, PTS has found a sustainable solution for manufacturing complex components quickly and efficiently, while being able to respond to new market demands.