Hesotec Electrify GmbH

EASY ARC Welding Robot Station at hesotec electrify

Company Background

Hesotec electrify GmbH, based in Dinslaken and led by CEO Georg Hellmich, is dedicated to meeting the growing demand for electromobility and charging infrastructure. Originally active in sheet metal and pipe processing for charging and vehicle components, the company now develops and manufactures compact, space-saving electric vehicle charging stations for both public and private sectors.

Automated Welding Solutions for Modern Charging Stations with EASY ARC

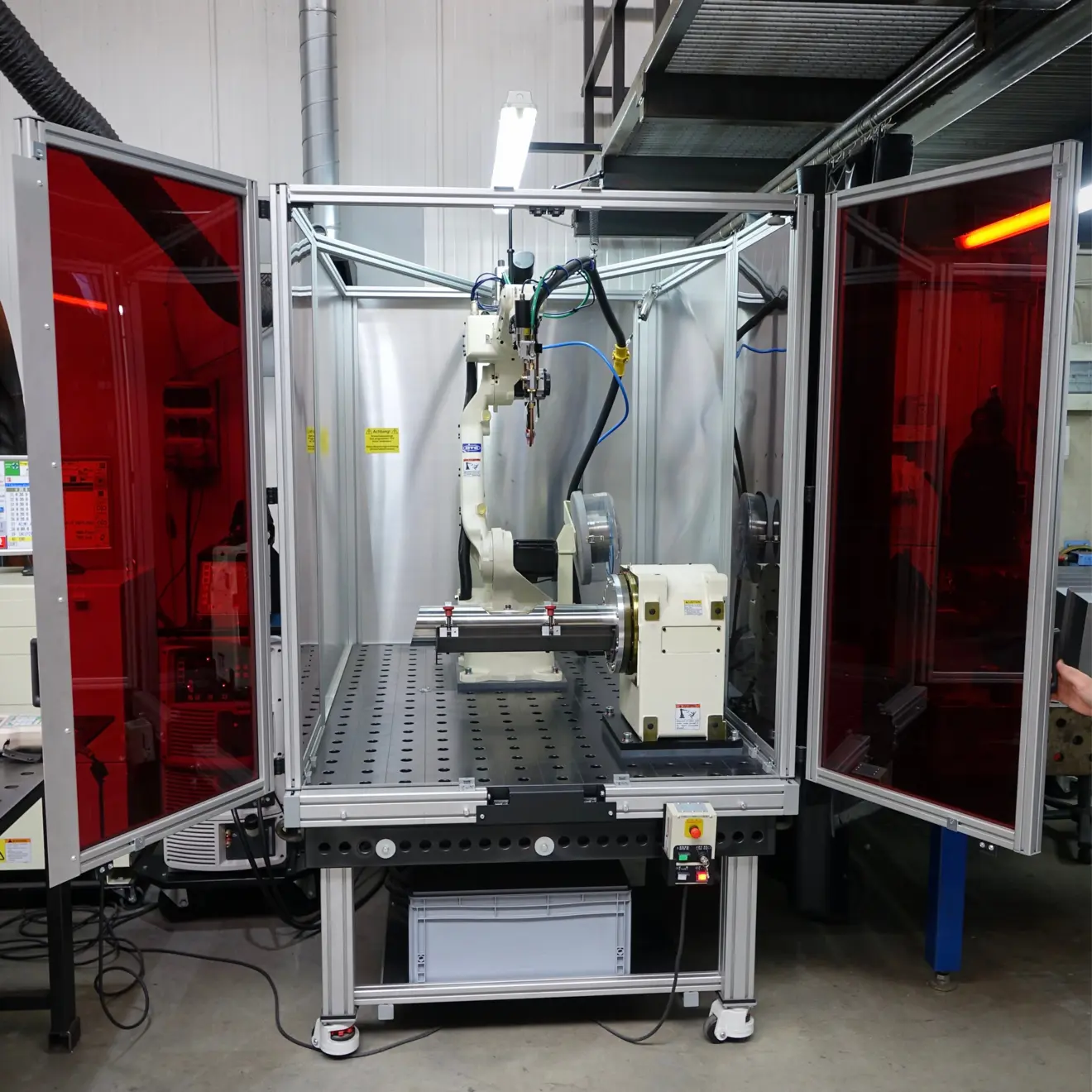

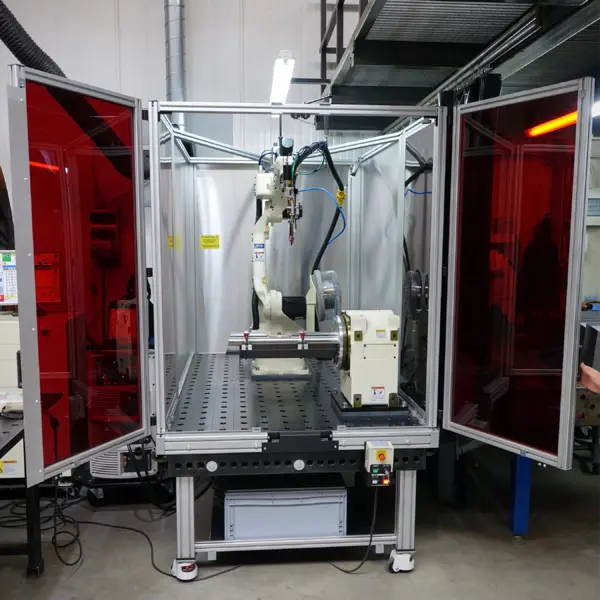

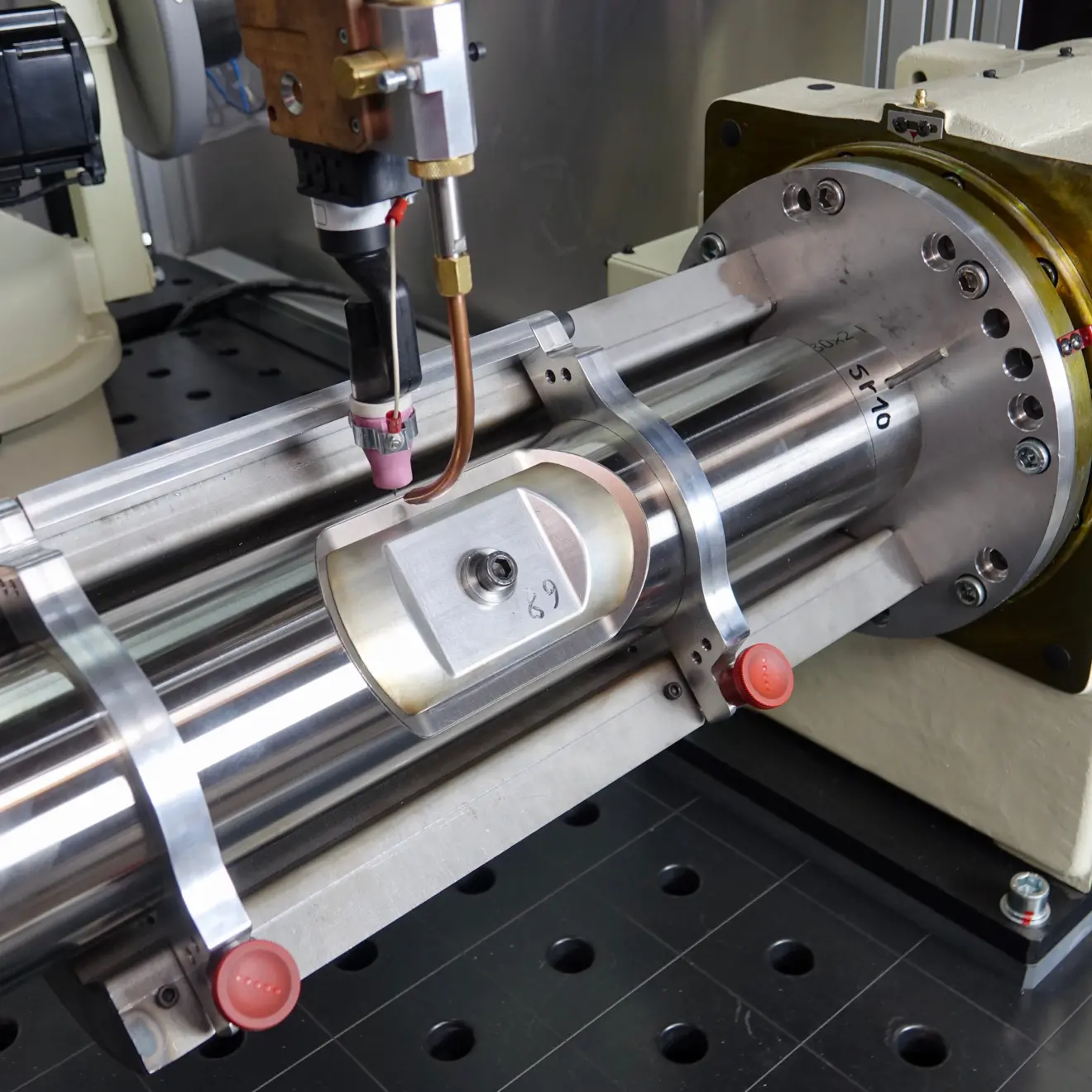

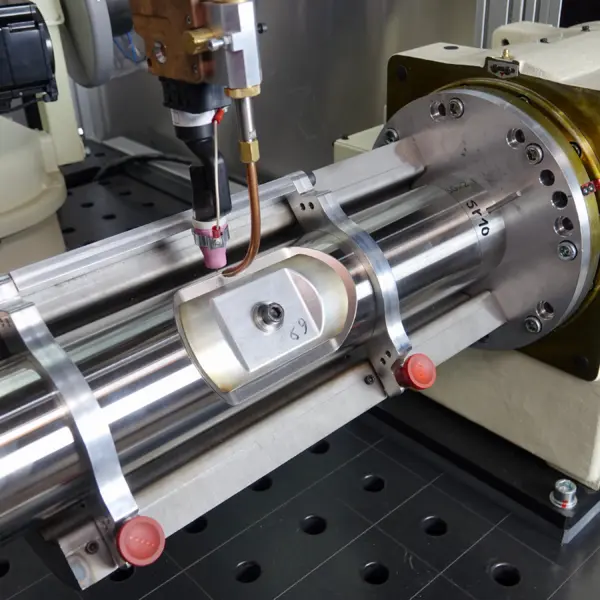

To meet the increasing demand for high-quality and precisely manufactured charging stations, hesotec electrify invested in the EASY ARC welding robot station from OTC DAIHEN EUROPE in 2020. The system enables automated TIG welding and ensures seamless connections for the enclosures of the charging stations.

Technical Details of the Welding Station:

- Welding Robot: FD-V8 for precise TIG welding

- Power Source: Water-cooled Welbee A350P for consistent welding results

- Equipment: FD-11 control unit, 3D welding table, horizontal rotary positioner, and complete safety enclosure

Improved Production Efficiency and Quality Assurance

The EASY ARC station enabled hesotec electrify to significantly reduce production time and scrap during the manufacturing of charging station enclosures. In contrast to manual and partially laser-welded processes that required significant rework, the EASY ARC system creates stable, gap-free connections. The high precision and reliability of the welding station were key factors for Hellmich to further automate production processes and improve efficiency.

Advantages of the EASY ARC Station for hesotec electrify:

- Flexibility and Expandability: The station allows for quick adjustments and expansions, making both small and large-scale production efficient.

- Fast Integration: The EASY ARC was quickly integrated into operations without external training. Experienced welders at hesotec electrify were trained in just a few days.

- Stability and Predictability: By automating the welding processes, hesotec electrify is able to deliver precise welding work continuously and with consistently high quality.

Initial Successes and Production Capacity

The EASY ARC welding robot station has already proven itself in large-scale projects at hesotec electrify: In one shift, up to 100 charging stations were produced and delivered on time to customers, including a major Danish client. Thanks to the stable welding processes and automated handling, the company was able to accept and successfully complete orders across Europe.

Flexible Product Portfolio for Electromobility

The charging station models developed by hesotec electrify offer flexible solutions for commercial and private customers. The portfolio ranges from space-saving wallboxes to standalone charging stations with load management and Wi-Fi. This variety allows the company to serve a broad market segment, from cities and municipalities to private customers who are increasingly adopting electromobility.

Conclusion

The EASY ARC welding robot station helps hesotec electrify meet the growing demand for EV charging stations while ensuring the highest quality and efficiency. The investment in the EASY ARC system has strengthened the company's competitiveness by enabling rapid adjustments and smooth production starts. The company is now well-positioned to meet the dynamic demands of the electromobility market.