Success Stories

Fully Automated Laser Welding System at RATIONAL GmbH

Efficient Solution for Workforce Shortages and Production Optimization

Company Background

RATIONAL GmbH, founded in 1973 with just 18 employees, has grown into a global leader in commercial steam cooking technology. Based in Landsberg, the company now has over 2,200 employees across 31 subsidiaries worldwide, including a significant number of trained chefs. However, the increasing demand and the high-quality standards for its steam cooking devices present ongoing challenges, especially amid skilled labor shortages. Previous manual production processes created a bottleneck, which led RATIONAL to automate the handling and welding processes for its cooking chamber production entirely.

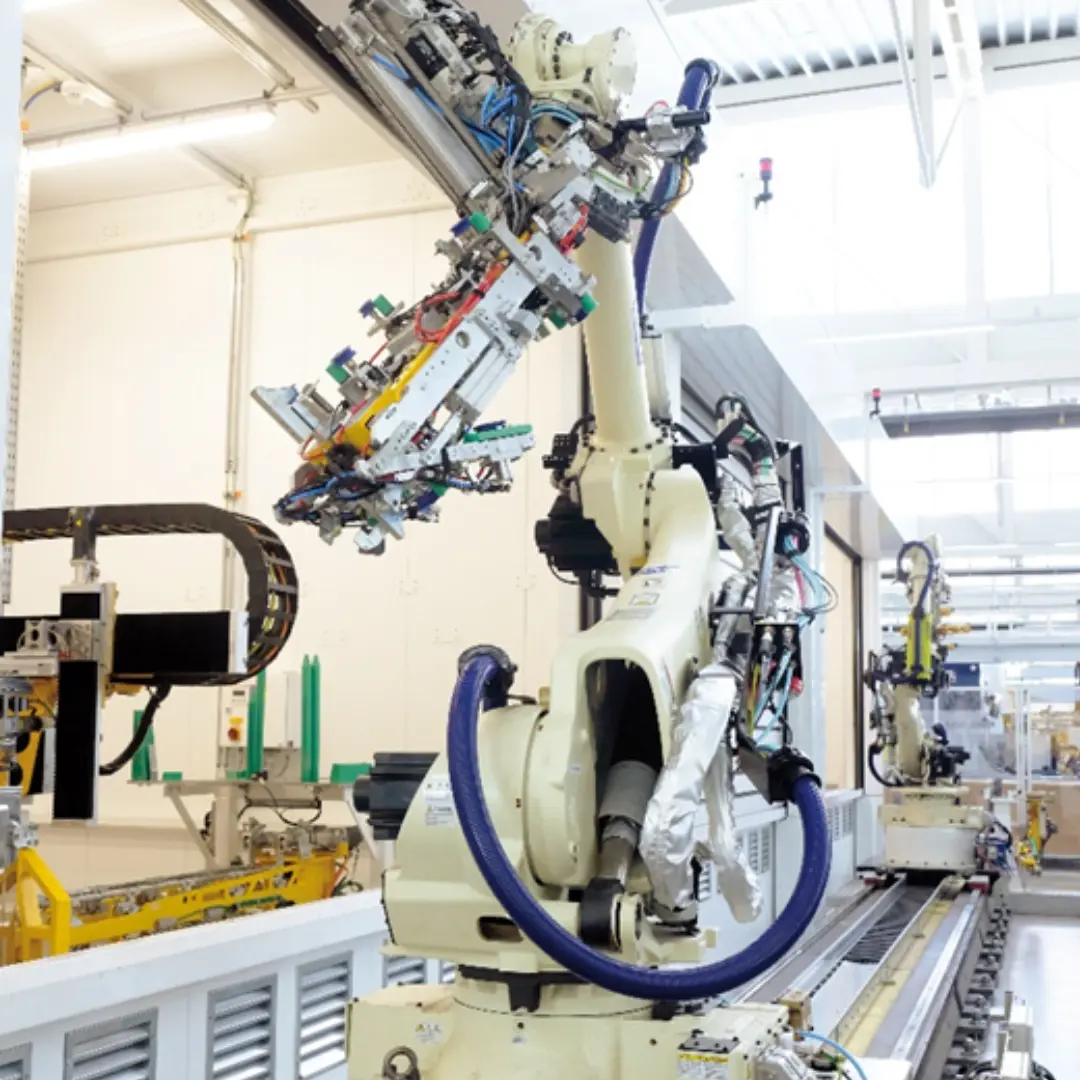

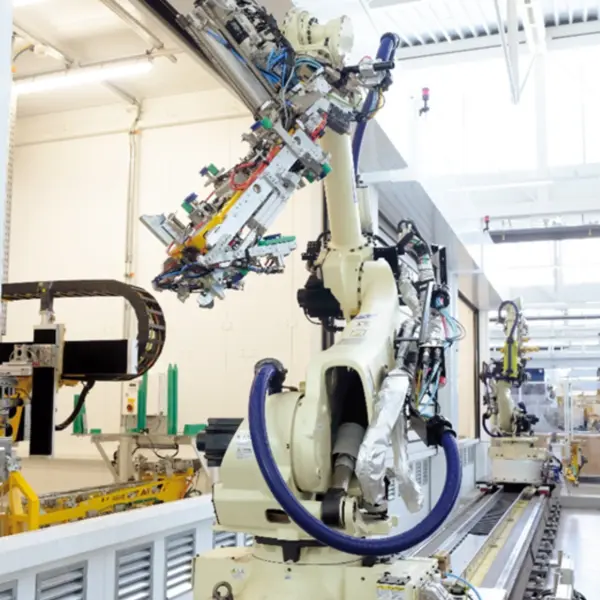

Laser Welding Solution from LASOtech and OTC – Fully Automated Production

To achieve complete automation of its cooking chamber production, RATIONAL partnered with LASOtech Systems GmbH, a German specialist in custom machinery and automation solutions. A subsidiary of DAIHEN Corporation since 2019, LASOtech brings extensive expertise in the design, construction, and integration of automated welding solutions. RATIONAL selected OTC Daihen technology for the laser welding cells, as they best met the high hygienic and aesthetic standards required for the stainless steel components in the cooking chamber. Unlike plasma or TIG welding, which generate more heat and risk metal distortion, laser welding enables precise joining of thin stainless steel without deformation.

Technical Features of the Laser Welding System:

- Robotic Technology: OTC FD-V210 robot for material handling and FD-V166 robot for welding processes

- Laser Welding Cells: Four laser welding cells supplied by eight material stations

- Coordination: Central PLC control system synchronizes the robots and stations for seamless operation

Flexible Use and Benefits for Industrial Scale Production

The laser welding system at RATIONAL provides a level of precision that manual work could not achieve. Thanks to the automated handling and welding technology, the production process is efficient without needing a high number of skilled laborers. The system operates three identical setups for smaller units and one setup for larger cooking chambers, enabling continuous three-shift production. This allows RATIONAL to maintain consistently high quality at rapid production speeds.

Advantages and Services of the Fully Automated Laser Welding System:

- Capacity and Flexibility: The system can accommodate variable lot sizes and different cooking chamber configurations based on model requirements

- Quality Standards: ISO-compliant production with precise laser weld seams, ensuring no distortion or oxidation for the high standards required in commercial kitchen technology

- Safety Management: The RMU (Robot Monitoring Unit) ensures precise and secure robot positioning at all times

Efficiency and User-Friendly Operation

The innovative laser welding system at RATIONAL requires only a single operator. The previously manual and labor-intensive welding tasks are now automated, ensuring the highest levels of accuracy. The integration of the OTC FD-V210 and FD-V166 robots allows for precise circular seams, supported by gas shields to prevent oxidation. OTC’s robust robot technology not only provides precise welding quality but also guarantees long-term stability and reliability due to its sturdy construction.

Conclusion

The LASOtech-implemented laser welding system, powered by OTC DAIHEN EUROPE technology, provides RATIONAL with a tailored solution that meets the increasing demands of the industry while offsetting skilled labor shortages. By combining advanced robotics, precise laser welding, and intelligent control systems, RATIONAL can achieve efficient and scalable production. This enables high-quality, cost-effective production that sets new standards for the future of automated manufacturing in the commercial kitchen equipment sector.