Success Stories

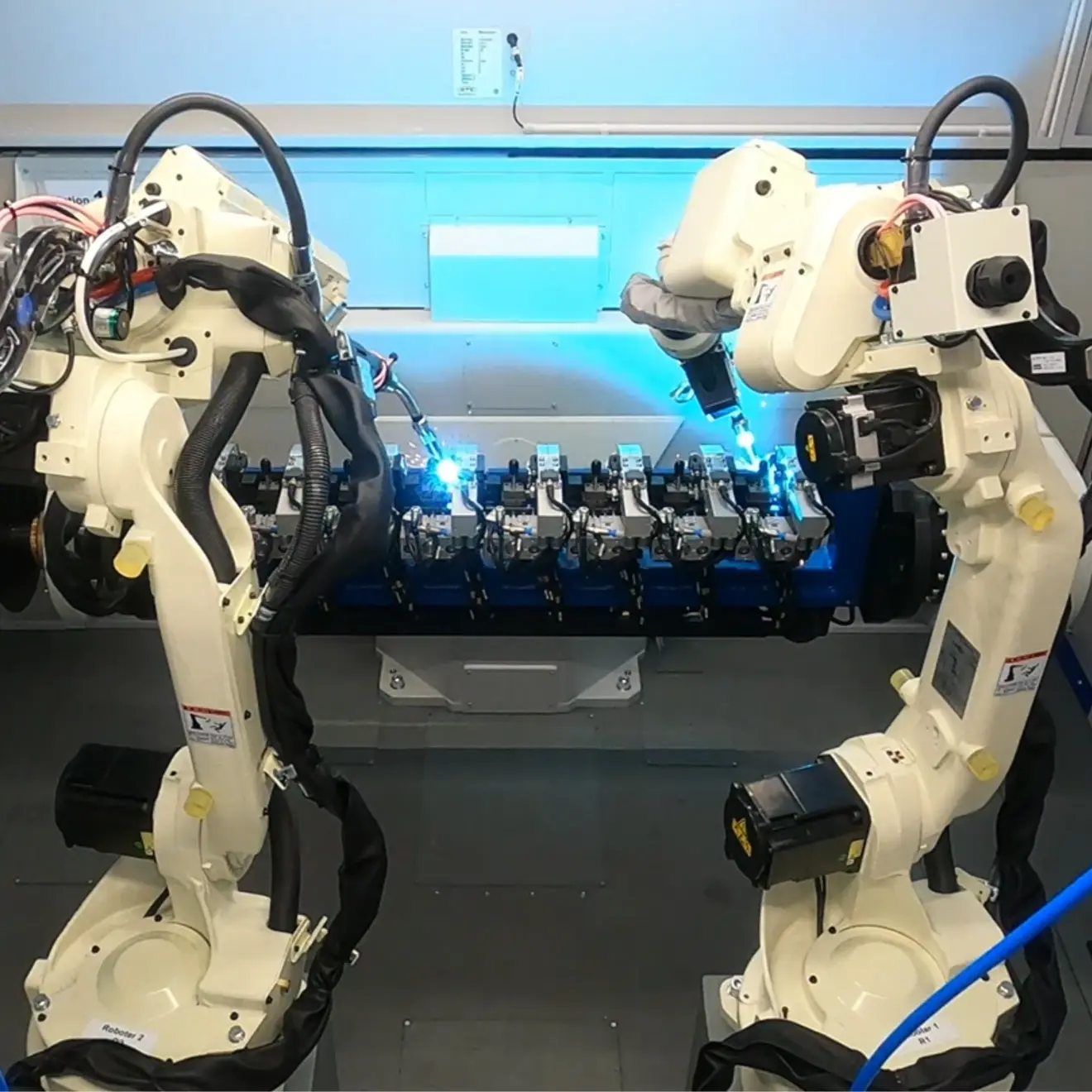

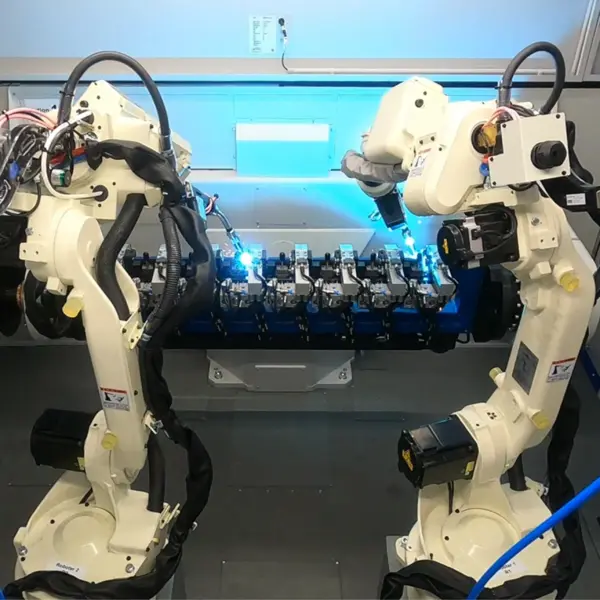

OTC Cube 04 Welding Robot Station at a Leading Automotive Supplier

Company Background

A renowned automotive supplier, specializing in high-precision and high-quality components for the automotive industry, turned to OTC DAIHEN EUROPE to find a customized solution for their production needs. The goal was to optimize the manufacturing of vehicle parts while increasing productivity without compromising on quality.

Automated Welding Solutions for Mass Production with the OTC Cube 04 System

To meet the growing demand for high production volumes with consistently high quality, the company decided in 2023 to implement the OTC Cube 04 robot station. This customized solution utilizes OTC's SynchroFeed process, replacing the previous TIG welding process. As a result, production speed increased significantly while maintaining the high-quality standards required in the automotive industry.

Technical Details of the Welding Station:

- • Welding Robots: Two FD19-B6 robots for precise welding in mass production

• Positioning System: Horizontal rotary positioner HP-1500 for accurate component positioning

• Process Control: OTC AM software to ensure quality and traceability in real time

• Process: OTC SynchroFeed for efficient and controlled wire feed welding

Production Boost and Quality Control

With the integration of the OTC Cube 04, the automotive supplier was able to double production and meet the requirements for flexibility and precision. The SynchroFeed process ensures uniform wire feeding, minimal heat input, and high welding speeds while preventing material deformation. The Cube system guarantees that the weld seams are consistently of high quality and free from porosity, meeting the stringent quality demands of the automotive sector.

Benefits of the OTC Cube 04 for the Customer:

- • Maximum Flexibility and Adaptability: The Cube system allows for quick adjustments to different manufacturing requirements and is suitable for both single-piece and mass production.

• Efficient Start-Up: The rapid setup and easy integration of the OTC Cube 04 into existing production processes allowed for seamless handover and commissioning in just a few days.

• Reliable Quality and Predictability: The automated welding process enables the automotive supplier to ensure consistently high-quality welds while optimizing production times.

Initial Successes and Production Capacity

Already in the initial phase of operation, the OTC Cube 04 proved its worth in mass production. The system’s flexibility allowed for efficient and flawless welding even in large-scale production runs. Thanks to stable process control and quick commissioning, the customer was able to significantly increase production output and expand their capacity in the global market.

Conclusion

The OTC Cube 04 welding robot station enabled the automotive supplier to meet the growing demands of the automotive industry by optimizing both production speed and weld quality. The investment in this turnkey solution has future-proofed the company and strengthened its competitiveness through innovative automation solutions. With the OTC Cube 04, the customer is well-positioned to meet the challenges of the dynamic automotive industry and continue delivering high-quality, precise components.