teaching with minimized production down-time

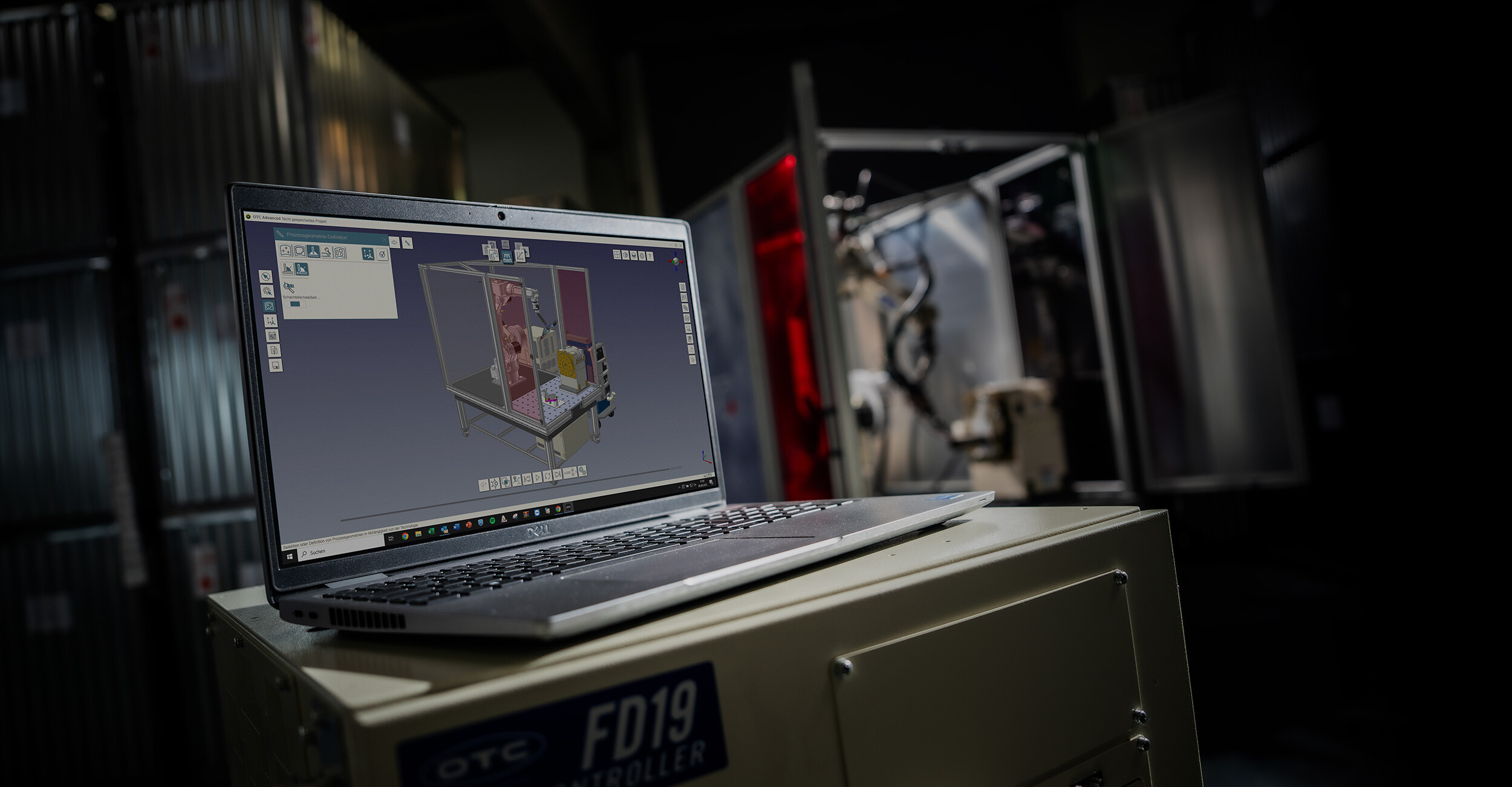

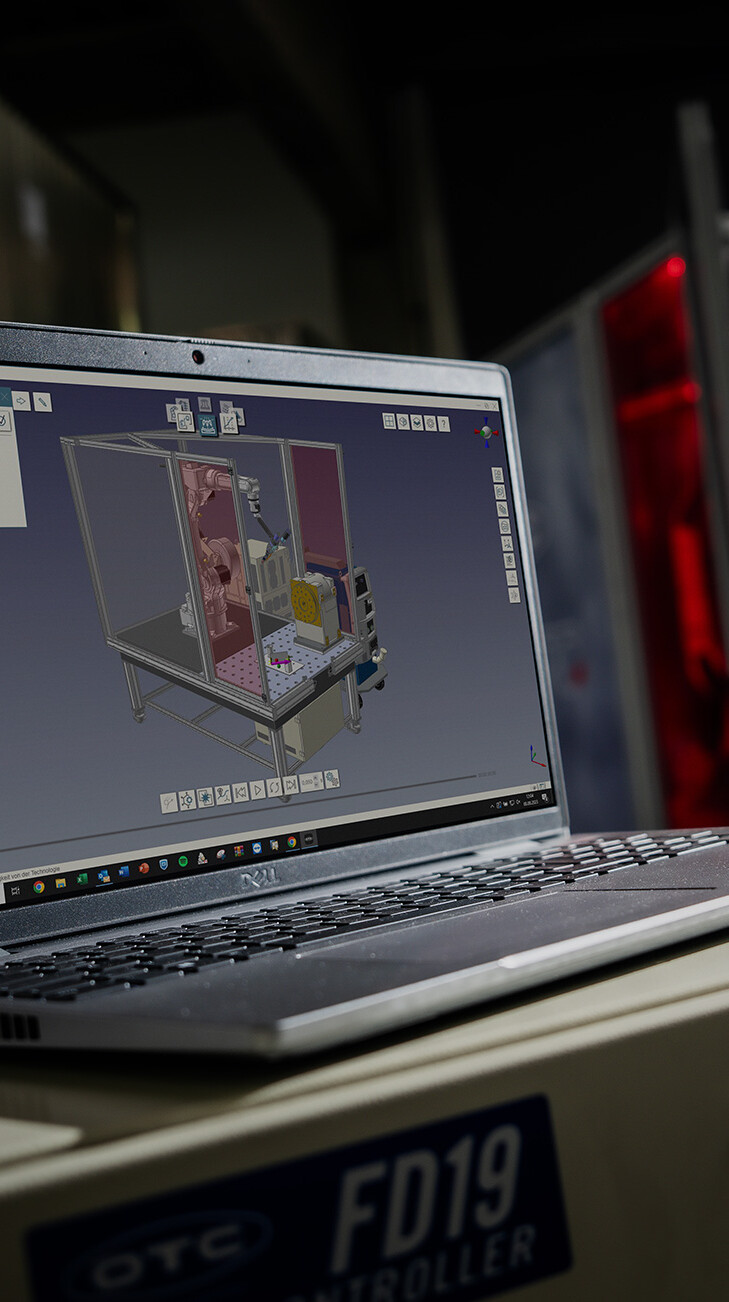

OUR OTC DAIHEN OFFLINE TEACHING SYSTEMS

You need to produce on maximal flexibility and small batch sizes? OTC DAIHEN supports you with appropriate offline teaching software that reduce downtime and costs, increase flexibility, improve safety and improve quality. Offline programming is a mighty software tool to create, simulate and test automation programs without the need for physical interaction.

Improvements to your system

Reduced downtime:

- creation and testing of robotic programs without interrupting production processes, that lead to reduced downtime and increased productivity

Reduced costs:

- eliminate the need for physical hardware setup, maintance and repair

- optimized cycle times increase output

Increased flexibility:

- possible testing and optimizing of robotic programs under various scenarios without the need for physical reconfiguration

Improved safety:

- testing of programs in a virtual environment without the need for physical intervention

Improved quality:

- optimization of robotic programs prior to physical implementation

- reduction of errors and defects probability

FD-ST

FD-ST is a basic software without license fees, compatible with the robot generations FD11 and FD19.

Functional scope:

- Software user interface identical to teach pendant

- Checking of accessibility and operation range

- Automatic programming of the welding seam

- Cycle time calculation

- Simulation of the automation program

Offline programming in cooperation with CENIT

OTC DAIHEN offers a full-scale offline software based on CENIT FASTSUITE. Three scalable versions are available to meet specific customer requirements.

All versions incorporate modern CAD-based offline programming. After importing CAD data, modern automatisms are immediately available, including powerful functions for automatic recognition of fillet welds, forced-position interpolation, mirroring, and cloning recurring weld paths and patterns, in addition to all important welding parameters. Once programmed, the system can be directly downloaded to the control system.

The versions Advanced and Integrator featuring a fixture builder, a computer-aided function that can quickly and flexibly design a suitable support fixture for any type of free form and export it immediately via CAD file.

Exclusively the version Integrator provides all necessary functions to expand existing libraries and create new components individually, such as traversing axes, positioners, and other peripherals. This allows for customization and flexibility in designing automation systems, making programming even more efficient and tailored to specific needs.

Version OTC Easy Teach

- Developed especially for Easy Arc

- Digital twin included

- Basic welding function (MIG/MAG/TIG)

Version OTC Integrator

- Developed especially for system integrators

- All functions from version advanced

- Neccessary to build digital twin

- Creation of peripherals, such as positioners, external axis etc.

Version OTC Advanced

- Ideal for end user

- Digital twin programmed seperatly to the customer system

- Complete OTC welding equipment support

- Complete OTC sensoric support

- Welding fixture builder assistent

- External axis support (slider, positioner, ect.)

- Multirobot stations

Discover more